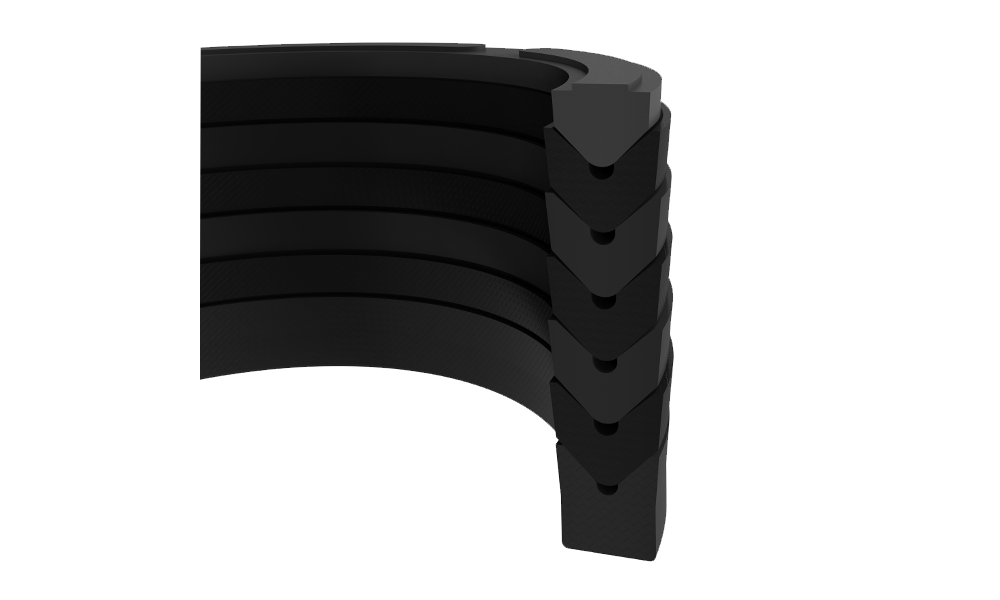

Rod Packing

| KASTAŞ NO | d(f8) | D(H9) | B(-0/+0,2) | n |

|---|---|---|---|---|

| K01-008 | 8 | 18 | 18,5 | 4 |

| K01-010 | 10 | 20 | 18,5 | 4 |

| K01-012 | 12 | 22 | 18,5 | 4 |

| K01-013 | 13,5 | 25 | 16,5 | 4 |

| K01-014 | 14 | 24 | 18,5 | 4 |

| K01-015 | 15 | 25 | 18,5 | 4 |

| K01-015/1 | 15 | 32 | 25 | 6 |

| K01-016 | 16 | 26 | 18,5 | 4 |

| K01-018 | 18 | 28 | 18,5 | 4 |

| K01-018/1 | 18 | 32 | 23,5 | 4 |

| K01-020 | 20 | 30 | 18,5 | 4 |

| K01-020/1 | 20 | 32 | 22,5 | 4 |

| K01-022 | 22 | 32 | 18,5 | 4 |

| K01-022/1 | 22 | 34 | 22,5 | 4 |

| K01-025 | 25 | 37 | 22,5 | 4 |

| K01-025/1 | 25 | 40 | 22,5 | 6 |

| K01-028 | 28 | 40 | 22,5 | 4 |

| K01-028/1 | 28 | 43 | 22,5 | 6 |

| K01-030 | 30 | 42 | 22,5 | 4 |

| K01-030/1 | 30 | 45 | 22,5 | 6 |

| K01-030/2 | 30 | 50 | 37 | 6 |

| K01-032 | 32 | 44 | 22,5 | 4 |

| K01-032/1 | 32 | 47 | 22,5 | 6 |

| K01-032/2 | 32 | 45 | 22,5 | 4 |

| K01-035 | 35 | 47 | 22,5 | 4 |

| K01-035/1 | 35 | 50 | 22,5 | 6 |

| K01-036 | 36 | 48 | 22,5 | 4 |

| K01-036/1 | 36 | 51 | 22,5 | 6 |

| K01-040 | 40 | 52 | 22,5 | 4 |

| K01-040/1 | 40 | 55 | 22,5 | 6 |

| K01-040/2 | 40 | 55 | 25 | 6 |

| K01-040/3 | 40 | 56 | 22,5 | 6 |

| K01-042 | 42 | 54 | 22,5 | 4 |

| K01-042/1 | 42 | 57 | 22,5 | 6 |

| K01-045 | 45 | 60 | 22,5 | 6 |

| K01-045/1 | 45 | 65 | 22,5 | 6 |

| K01-045/2 | 45 | 55 | 22 | 4 |

| K01-045/3 | 45 | 62 | 26 | 6 |

| K01-047 | 47 | 65 | 33 | 6 |

| K01-048 | 48 | 63 | 22,5 | 6 |

| K01-050 | 50 | 65 | 22,5 | 6 |

| K01-050/1 | 50 | 70 | 30 | 6 |

| K01-055 | 55 | 70 | 22,5 | 6 |

| K01-055/1 | 55 | 75 | 30 | 6 |

| K01-055/2 | 55 | 67 | 24 | 4 |

| K01-056 | 56 | 71 | 22,5 | 6 |

| K01-056/1 | 56 | 76 | 37 | 6 |

| K01-056/2 | 56 | 72 | 46 | 6 |

| K01-060 | 60 | 75 | 22,5 | 6 |

| K01-060/1 | 60 | 80 | 37 | 6 |

| K01-060/3 | 60 | 85 | 37 | 8 |

| K01-063 | 63 | 78 | 22,5 | 6 |

| K01-063/1 | 63 | 83 | 37 | 6 |

| K01-063/2 | 63,5 | 78 | 40 | 4 |

| K01-065 | 65 | 80 | 22,5 | 6 |

| K01-065/1 | 65 | 85 | 40 | 6 |

| K01-070 | 70 | 85 | 22,5 | 6 |

| K01-070/1 | 70 | 90 | 40 | 6 |

| K01-075 | 75 | 90 | 22,5 | 6 |

| K01-075/1 | 75 | 95 | 40 | 6 |

| K01-075/2 | 75 | 87 | 25 | 4 |

| K01-075/3 | 75 | 100 | 34 | 8 |

| K01-078 | 78 | 100 | 35 | 7 |

| K01-080 | 80 | 95 | 22,5 | 6 |

| K01-080/1 | 80 | 100 | 40 | 6 |

| K01-085 | 85 | 100 | 22,5 | 6 |

| K01-085/1 | 85 | 105 | 40 | 6 |

| K01-085/2 | 85 | 95 | 22,5 | 4 |

| K01-090 | 90 | 105 | 22,5 | 6 |

| K01-090/1 | 90 | 110 | 40 | 6 |

| K01-090/2 | 90 | 110 | 26 | 6 |

| K01-090/3 | 90 | 110 | 22,5 | 6 |

| K01-095 | 95 | 120 | 50 | 8 |

| K01-100 | 100 | 115 | 30 | 6 |

| K01-100/1 | 100 | 120 | 40 | 6 |

| K01-105 | 105 | 120 | 30 | 6 |

| K01-105/1 | 105 | 125 | 40 | 6 |

| K01-105/2 | 105 | 130 | 40 | 8 |

| K01-110 | 110 | 125 | 30 | 6 |

| K01-110/1 | 110 | 130 | 40 | 6 |

| K01-115 | 115 | 130 | 30 | 6 |

| K01-115/1 | 115 | 140 | 46 | 6 |

| K01-115/2 | 115 | 135 | 30 | 8 |

| K01-120 | 120 | 140 | 49 | 6 |

| K01-120/1 | 120 | 145 | 46 | 8 |

| K01-125 | 125 | 140 | 34 | 6 |

| K01-125/1 | 125 | 150 | 46 | 8 |

| K01-130 | 130 | 155 | 42,5 | 8 |

| K01-135 | 135 | 160 | 55 | 8 |

| K01-135/1 | 135 | 160 | 40 | 8 |

| K01-140 | 140 | 155 | 34 | 6 |

| K01-140/1 | 140 | 165 | 46 | 8 |

| K01-140/2 | 140 | 160 | 32 | 6 |

| K01-140/3 | 140 | 170 | 60 | 8 |

| K01-150 | 150 | 170 | 40 | 6 |

| K01-150/1 | 150 | 180 | 60 | 8 |

| K01-160 | 160 | 180 | 40 | 6 |

| K01-160/1 | 160 | 190 | 60 | 8 |

| K01-160/2 | 160 | 175 | 34 | 4 |

| K01-165 | 165 | 195 | 50,5 | 8 |

| K01-170 | 170 | 190 | 40 | 6 |

| K01-180 | 180 | 200 | 40 | 6 |

| K01-180/1 | 180 | 210 | 60 | 8 |

| K01-190 | 190 | 220 | 42 | 8 |

| K01-200 | 200 | 220 | 40 | 6 |

| K01-200/1 | 200 | 230 | 60 | 8 |

| K01-210 | 210 | 240 | 50 | 8 |

| K01-215 | 215 | 245 | 41 | 8 |

| K01-220 | 220 | 240 | 40 | 6 |

| K01-230 | 230 | 260 | 58 | 8 |

| K01-240 | 240 | 270 | 60 | 8 |

| K01-240/1 | 240 | 260 | 46 | 6 |

| K01-250 | 250 | 270 | 42 | 6 |

| K01-260 | 260 | 290 | 60 | 8 |

| K01-300 | 300 | 330 | 60 | 8 |

| K01-310 | 310 | 340 | 60 | 8 |

| K01-320 | 320 | 350 | 60 | 8 |

| K01-320/1 | 320 | 360 | 46 | 12 |

| K01-330 | 330 | 360 | 60 | 8 |

| K01-360 | 360 | 390 | 60 | 8 |

| K01-360/1 | 360 | 400 | 55 | 12 |

| K01-370 | 370 | 400 | 55 | 8 |

| K01-400 | 400 | 440 | 65 | 12 |

| K01-400/1 | 400 | 430 | 46 | 8 |

| K01-420 | 420 | 460 | 80 | 12 |

| K01-440 | 440 | 480 | 68 | 12 |

| K01-450 | 450 | 490 | 65 | 12 |

|

||||||||||||||||||||||||

|

K01 is a seven piece single acting sealing set which consists of one reinforced cotton fabric backup ring , one thermoplastic header ring , three reinforced cotton fabric middle rings , and two elastomeric nitrile rubber middle rings. PRODUCT ADVANTAGES APPLICATION |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

| SURFACE ROUGHNESS | Ra | Rmax |

| Sliding Surface Ød | ≤0.4 μm | ≤3.2 μm |

| Groove Base ØD | ≤1.6 μm | ≤6.3 μm |

| Groove Flanks B | ≤3.2 μm | ≤16 μm |

| Note: It is recommended to have 50% to 90% of the working surface material contact area value. | ||

|

INSTALLATION |

||

|

NOTES |

||