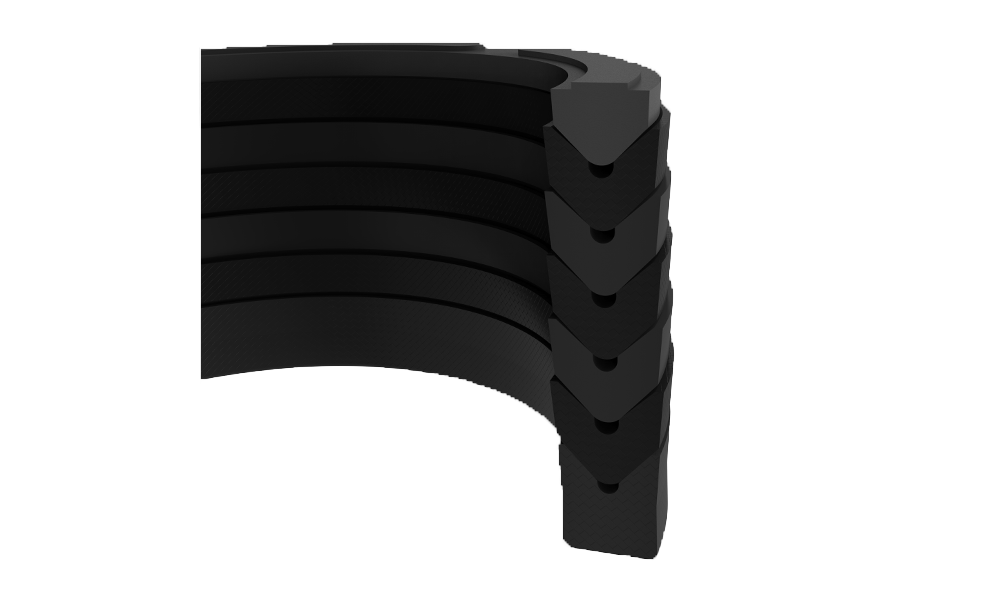

Rod Packing

| KASTAŞ NO | d(f8) | D(H9) | B(-0/+0,2) | n |

|---|---|---|---|---|

| K04-012 | 12,75 | 25,4 | 19,05 | 4 |

| K04-019 | 19,05 | 28,5 | 17,46 | 4 |

| K04-020 | 20,62 | 33,32 | 33,32 | 4 |

| K04-022 | 22,22 | 34,92 | 19,05 | 4 |

| K04-031 | 31,75 | 44,45 | 25,4 | 4 |

| K04-038 | 38,1 | 50,8 | 25,4 | 4 |

| K04-038/1 | 38,1 | 53,98 | 25,4 | 4 |

| K04-044 | 44,45 | 57,15 | 25,4 | 4 |

| K04-044/1 | 44,45 | 63,5 | 38,1 | 6 |

| K04-044/2 | 44,45 | 69,85 | 50,8 | 8 |

| K04-050 | 50,8 | 63,5 | 25,4 | 4 |

| K04-050/1 | 50,8 | 65 | 25,4 | 4 |

| K04-050/2 | 50,8 | 66,67 | 25,4 | 6 |

| K04-050/3 | 50,8 | 69,85 | 25,4 | 6 |

| K04-053 | 53,98 | 69,85 | 28,5 | 6 |

| K04-057 | 57,16 | 76,2 | 25,4 | 6 |

| K04-063 | 63,5 | 76,2 | 28,5 | 4 |

| K04-063/1 | 63,5 | 78 | 41 | 4 |

| K04-063/2 | 63,5 | 79,37 | 28,5 | 6 |

| K04-063/3 | 63,5 | 82,55 | 28,5 | 6 |

| K04-069 | 69,85 | 88,9 | 31,75 | 6 |

| K04-076 | 76,2 | 88,9 | 25,4 | 4 |

| K04-076/1 | 76,2 | 95,25 | 31,75 | 6 |

| K04-076/2 | 76,2 | 101,6 | 38.1 | 8 |

| K04-082 | 82,55 | 101,6 | 31.75 | 6 |

| K04-088 | 88,9 | 104,8 | 28,5 | 6 |

| K04-088/1 | 88,9 | 107,95 | 30,16 | 6 |

| K04-088/2 | 88,9 | 114,3 | 38,1 | 8 |

| K04-095 | 95,25 | 114,3 | 30,16 | 6 |

| K04-101 | 101,6 | 127 | 38,1 | 8 |

| K04-107 | 107,95 | 127 | 31,75 | 6 |

| K04-107/1 | 107,95 | 130,18 | 38,1 | 6 |

| K04-114 | 114,3 | 133,36 | 31,75 | 6 |

| K04-114/1 | 114,3 | 139,7 | 38,1 | 8 |

| K04-127 | 127 | 158,75 | 60 | 8 |

| K04-209 | 209,55 | 228,6 | 38,1 | 6 |

|

||||||||||||||||||||||||

|

K04 is a seven piece single acting sealing set which consists of one reinforced cotton fabric backup ring , one thermoplastic header ring , three reinforced cotton fabric middle rings , and two elastomeric nitrile rubber middle rings. PRODUCT ADVANTAGES APPLICATION |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

| SURFACE ROUGHNESS | Ra | Rmax |

| Sliding Surface Ød | ≤0.4 μm | ≤3.2 μm |

| Groove Base ØD | ≤1.6 μm | ≤6.3 μm |

| Groove Flanks B | ≤3.2 μm | ≤16 μm |

| Note: It is recommended to have 50% to 90% of the working surface material contact area value | ||

|

INSTALLATION |

||

|

NOTES |

||