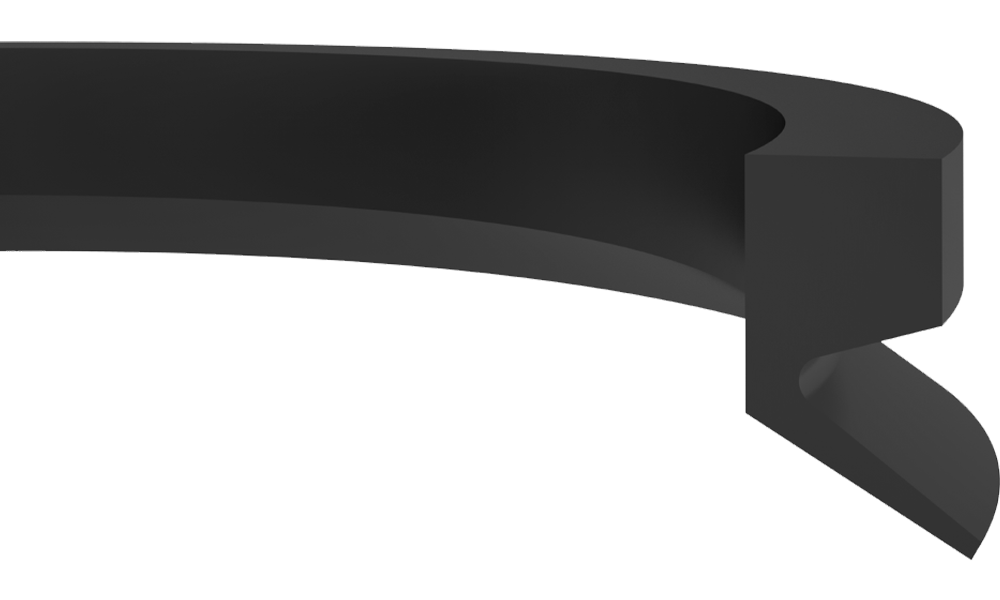

K14

V-Ring

| KASTAŞ NO | d | D min | Ø d1 | b1 | b2 | b3 | D2 max. |

|---|---|---|---|---|---|---|---|

| K14 150 A | 145-155 | d+21 | 135 | 12,8 | 7,9 | 10,5±1,5 | d+4 |

| K14-010 A | 9,5-11,5 | d+9 | 9 | 5,5 | 3,4 | 4,5±0,6 | d+2 |

| K14-010 S | 9,5-11,5 | d+9 | 9 | 7,7 | 5,6 | 6,7±0,6 | d+2 |

| K14-012 A | 11,5-13,5 | d+9 | 10,5 | 5,5 | 3,4 | 4,5±0,6 | d+2 |

| K14-012 S | 11,5-13,5 | d+9 | 10,5 | 7,7 | 5,6 | 6,7±0,6 | d+2 |

| K14-014 A | 13,5-15,5 | d+9 | 12,5 | 5,5 | 3,4 | 4,5±0,6 | d+2 |

| K14-014 S | 13,5-15,5 | d+9 | 12,5 | 7,7 | 5,6 | 6,7±0,6 | d+2 |

| K14-016 A | 15,5-17,5 | d+9 | 14 | 5,5 | 3,4 | 4,5±0,6 | d+2 |

| K14-016 S | 15,5-17,5 | d+9 | 14 | 7,7 | 5,6 | 6,7±0,6 | d+2 |

| K14-018 A | 17,5-19 | d+9 | 16 | 5,5 | 3,4 | 4,5±0,6 | d+2 |

| K14-018 S | 17,5-19 | d+9 | 16 | 7,7 | 5,6 | 6,7±0,6 | d+2 |

| K14-020 A | 19-21 | d+12 | 18 | 7,5 | 4,7 | 6,0±0,8 | d+2 |

| K14-020 S | 19-21 | d+12 | 18 | 10,5 | 7,9 | 9,0±0,8 | d+2 |

| K14-025 A | 24-27 | d+12 | 22 | 7,5 | 4,7 | 6,0±0,8 | d+2 |

| K14-025 S | 24-27 | d+12 | 22 | 10,5 | 7,9 | 9,0±0,8 | d+2 |

| K14-030 A | 29-31 | d+12 | 27 | 7,5 | 4,7 | 6,0±0,8 | d+3 |

| K14-030 S | 29-31 | d+12 | 27 | 10,5 | 7,9 | 9,0±0,8 | d+3 |

| K14-032 A | 31-33 | d+12 | 29 | 7,5 | 4,7 | 6,0±0,8 | d+3 |

| K14-032 S | 31-33 | d+12 | 29 | 10,5 | 7,9 | 9,0±0,8 | d+3 |

| K14-035 A | 33-36 | d+12 | 31 | 7,5 | 4,7 | 6,0±0,8 | d+3 |

| K14-035 S | 33-36 | d+12 | 31 | 10,5 | 7,9 | 9,0±0,8 | d+3 |

| K14-038 A | 36-38 | d+12 | 34 | 7,5 | 4,7 | 6,0±0,8 | d+3 |

| K14-038 S | 36-38 | d+12 | 34 | 10,5 | 7,9 | 9,0±0,8 | d+3 |

| K14-040 A | 38-43 | d+12 | 36 | 9 | 5,5 | 7,0±1,0 | d+3 |

| K14-040 S | 38-43 | d+15 | 36 | 13 | 9,5 | 11,0±1,0 | d+3 |

| K14-045 A | 43-48 | d+15 | 40 | 9 | 5,5 | 7,0±1,0 | d+3 |

| K14-045 S | 43-48 | d+15 | 40 | 13 | 9,5 | 11,0±1,0 | d+3 |

| K14-050 A | 48-53 | d+15 | 45 | 9 | 5,5 | 7,0±1,0 | d+3 |

| K14-050 S | 48-53 | d+15 | 45 | 13 | 9,5 | 11,0±1,0 | d+3 |

| K14-055 A | 53-58 | d+15 | 49 | 9 | 5,5 | 7,0±1,0 | d+3 |

| K14-055 S | 53-58 | d+15 | 49 | 13 | 9,5 | 11,0±1,0 | d+3 |

| K14-060 A | 58-63 | d+15 | 54 | 9 | 5,5 | 7,0±1,0 | d+3 |

| K14-060 S | 58-63 | d+15 | 54 | 13 | 9,5 | 11,0±1,0 | d+3 |

| K14-065 A | 63-68 | d+15 | 58 | 9 | 5,5 | 7,0±1,0 | d+3 |

| K14-065 S | 63-68 | d+15 | 58 | 13 | 9,5 | 11,0±1,0 | d+3 |

| K14-070 A | 68-73 | d+18 | 63 | 11 | 6,8 | 9,0±1,2 | d+4 |

| K14-070 S | 68-73 | d+18 | 63 | 15,5 | 11,3 | 13,5±1,2 | d+4 |

| K14-075 A | 73-78 | d+18 | 67 | 11 | 6,8 | 9,0±1,2 | d+4 |

| K14-075 S | 73-78 | d+18 | 67 | 15,5 | 11,3 | 13,5±1,2 | d+4 |

| K14-080 A | 78-83 | d+18 | 72 | 11 | 6,8 | 9,0±1,2 | d+4 |

| K14-080 S | 78-83 | d+18 | 72 | 15,5 | 11,3 | 13,5±1,2 | d+4 |

| K14-085 A | 83-88 | d+18 | 76 | 11 | 6,8 | 9,0±1,2 | d+4 |

| K14-085 S | 83-88 | d+18 | 76 | 15,5 | 11,3 | 13,5±1,2 | d+4 |

| K14-090 A | 88-93 | d+18 | 81 | 11 | 6,8 | 9,0±1,2 | d+4 |

| K14-090 S | 88-93 | d+18 | 81 | 15,5 | 11,3 | 13,5±1,2 | d+4 |

| K14-095 A | 93-98 | d+18 | 85 | 11 | 6,8 | 9,0±1,2 | d+4 |

| K14-095 S | 93-98 | d+18 | 85 | 15,5 | 11,3 | 13,5±1,2 | d+4 |

| K14-100 A | 98-105 | d+18 | 90 | 11 | 6,8 | 9,0±1,2 | d+4 |

| K14-100 S | 98-105 | d+18 | 90 | 15,5 | 11,3 | 13,5±1,2 | d+4 |

| K14-110 A | 105-115 | d+21 | 99 | 12,8 | 7,9 | 10,5±1,5 | d+4 |

| K14-110 S | 105-115 | d+21 | 99 | 18 | 13,1 | 15,5±1,5 | d+4 |

| K14-120 A | 115-125 | d+21 | 108 | 12,8 | 7,9 | 10,5±1,5 | d+4 |

| K14-120 S | 115-125 | d+21 | 108 | 18 | 13,1 | 15,5±1,5 | d+4 |

| K14-130 A | 125-135 | d+21 | 117 | 12,8 | 7,9 | 10,5±1,5 | d+4 |

| K14-130 S | 125-135 | d+21 | 117 | 18 | 13,1 | 15,5±1,5 | d+4 |

| K14-140 A | 135-145 | d+21 | 126 | 12,8 | 7,9 | 10,5±1,5 | d+4 |

| K14-140 S | 135-145 | d+21 | 126 | 18 | 13,1 | 15,5±1,5 | d+4 |

|

|||||||||||||||||||||||||

|

K14 is a V-Ring designed to be used for rotating shaft applications. PRODUCT ADVANTAGES APPLICATION |

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

| SURFACE ROUGHNESS | Ra | Rmax |

| Sliding Surface | ≤0.8 μm | ≤3 μm |

| Groove Base | ≤1.8 μm | ≤6.3 μm |

| Groove Flanks | ≤5 μm | ≤18 μm |

|

INSTALLATION |

||

|

NOTES |

||