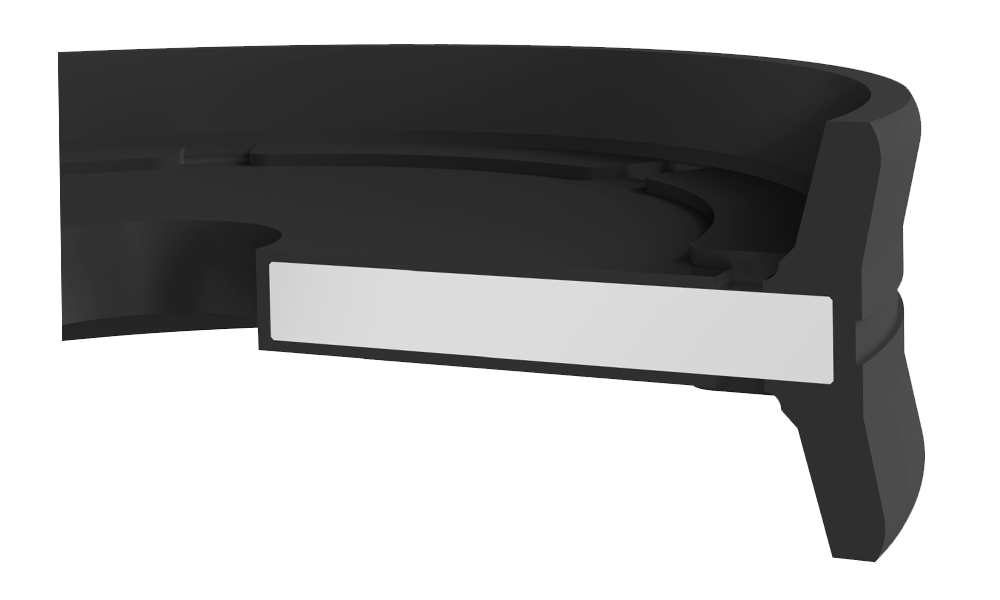

Pneumatic Piston Seal

| KASTAŞ NO | D (H11) | d (h9) | B | d1 | s1 | s |

|---|---|---|---|---|---|---|

| K25-020 | 20 | 5,2 | 8 | 12,2 | 1 | 1,4 |

| K25-025 | 25 | 8 | 12 | 14,5 | 3 | 4 |

| K25-025/2 | 25,4 | 6,35 | 12,7 | 9,40 | 2,5 | 3,50 |

| K25-026 | 26 | 8 | 12 | 15,5 | 3 | 4 |

| K25-028 | 28.58 | 6.35 | 12.7 | 12.58 | 2.5 | 3.5 |

| K25-031 | 31.75 | 6.35 | 14.29 | 15.75 | 2.5 | 3.5 |

| K25-032 | 32 | 8 | 15 | 16 | 3 | 4 |

| K25-035 | 35 | 8 | 15 | 19 | 3 | 4 |

| K25-036 | 36 | 8 | 15 | 20 | 3 | 4 |

| K25-040 | 40 | 10 | 18 | 23 | 4 | 5 |

| K25-044 | 44,45 | 6,35 | 14,28 | 23,46 | 2,5 | 3,50 |

| K25-050 | 50 | 10 | 18 | 29 | 4 | 5 |

| K25-050/2 | 50 | 16 | 20.5 | 25 | 4 | 5 |

| K25-050/7 | 50.8 | 9.53 | 15.88 | 15.75 | 3 | 4 |

| K25-057 | 57.15 | 9.53 | 15.88 | 34.65 | 3 | 4 |

| K25-060 | 60 | 12 | 22 | 36,8 | 4 | 5 |

| K25-060/1 | 60.33 | 9.53 | 15.88 | 37.83 | 3 | 4 |

| K25-062 | 62 | 15 | 22 | 39 | 5 | 6 |

| K25-063 | 63 | 12 | 22 | 40,5 | 5 | 6 |

| K25-069 | 69.85 | 9.53 | 19.05 | 47.35 | 4 | 5.5 |

| K25-070 | 70 | 12 | 22 | 47 | 5 | 6 |

| K25-073 | 73.03 | 9.53 | 19.05 | 48.03 | 4 | 5.5 |

| K25-075 | 75 | 15 | 22 | 52 | 5 | 6 |

| K25-075/1 | 75 | 12 | 22.5 | 52 | 5 | 6 |

| K25-076 | 76.2 | 12.7 | 19.05 | 51.2 | 4 | 5 |

| K25-080 | 80 | 16 | 25 | 55 | 5 | 6,5 |

| K25-080/4 | 80 | 16 | 22.5 | 55.2 | 5 | 6.5 |

| K25-080/5 | 80 | 20 | 22,5 | 55,2 | 5 | 6,5 |

| K25-082 | 82.55 | 12.7 | 19.05 | 57.55 | 4 | 5 |

| K25-088 | 88.9 | 12.7 | 22.23 | 63.9 | 5 | 6 |

| K25-090 | 90 | 16 | 25 | 65 | 5 | 6,5 |

| K25-100 | 100 | 16 | 25 | 75 | 5 | 6,5 |

| K25-100/4 | 100 | 12 | 25 | 75 | 5 | 6.5 |

| K25-100/6 | 100 | 20 | 26 | 75 | 5 | 6.5 |

| K25-107 | 107.95 | 12.7 | 22.23 | 82.96 | 5 | 6 |

| K25-110 | 110 | 18 | 25 | 85 | 6 | 7,5 |

| K25-114 | 114.3 | 19.05 | 22.23 | 79.3 | 5 | 6 |

| K25-125 | 125 | 20 | 30 | 90 | 8 | 10 |

| K25-125/1 | 125 | 20 | 26 | 90 | 6 | 7.5 |

| K25-127 | 127 | 19.05 | 25.4 | 92 | 6 | 7.5 |

| K25-130 | 130 | 20 | 29 | 95,00 | 8 | 10,00 |

| K25-140 | 140 | 20 | 30 | 95 | 10 | 12 |

| K25-150 | 150 | 20 | 30 | 105 | 10 | 12 |

| K25-152 | 152.4 | 19.05 | 25.4 | 107.4 | 6 | 7.5 |

| K25-160 | 160 | 27 | 31 | 115 | 10 | 12 |

| K25-160/3 | 160 | 20 | 30 | 130 | 10 | 10.7 |

| K25-165 | 165.1 | 19.05 | 25.4 | 120.1 | 6 | 7.5 |

| K25-180 | 180 | 27 | 31 | 135 | 10 | 12 |

| K25-190 | 190 | 20 | 30 | 160,4 | 10 | 12 |

| K25-200 | 200 | 27 | 35 | 150 | 12 | 15 |

| K25-200/5 | 200 | 30 | 35 | 150,00 | 8 | 10,60 |

| K25-202 | 202.2 | 31.75 | 38.1 | 150.5 | 10 | 11 |

| K25-250 | 250 | 30 | 35 | 200 | 12 | 16,5 |

| K25-253 | 253 | 44.45 | 41.27 | 180 | 12 | 15 |

| K25-320 | 320 | 36 | 40 | 278,5 | 15 | 18,6 |

| K25-400 | 400 | 40 | 50 | 320 | 20 | 23 |

|

||||||||||||||||||||||||||

|

K25 is a double acting complete piston seal which consists of a steel plate vulcanized with elastomeric nitrile rubber using special production methods. PRODUCT ADVANTAGES APPLICATION |

||||||||||||||||||||||||||

|

||||||||||||||||||||||||||

| SURFACE ROUGHNESS | Rmax | |

| Sliding Surface ØD | ≤0.4 μm | ≤3.2 μm |

|

INSTALLATION |

||

|

NOTES |

||