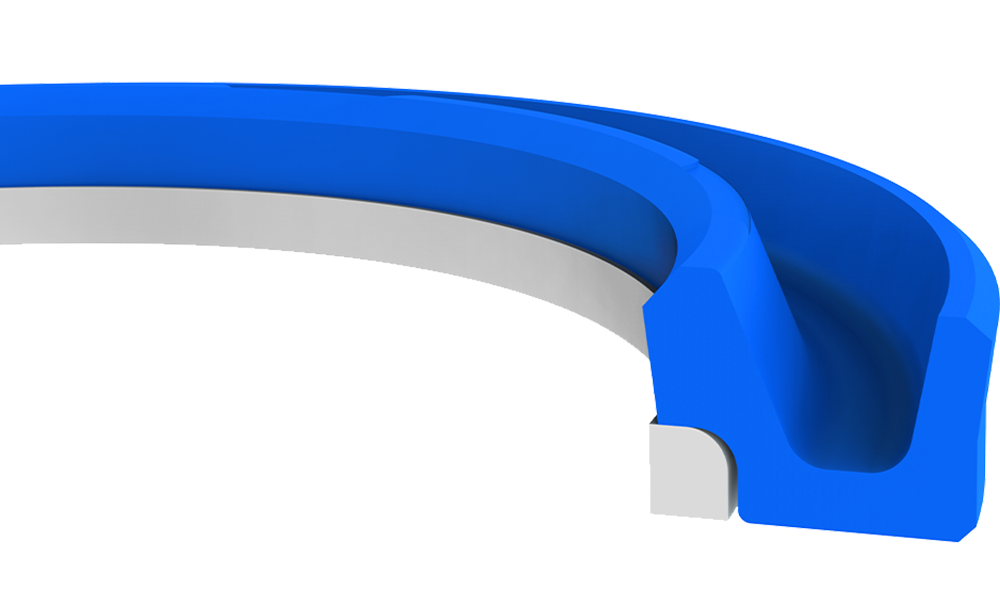

Buffer Seal

| KASTAŞ NO | d (f8) | D(H11) | B(-0/+0,2) | b | r | n |

|---|---|---|---|---|---|---|

| K29-032 PU | 32 | 42,7 | 4,2 | 3,9 | 0,2 | 5 |

| K29-035 PU | 35 | 45,7 | 4,2 | 3,9 | 0,2 | 5 |

| K29-036 PU | 36 | 46.7 | 4.2 | 3.9 | 0.2 | 5 |

| K29-038 PU | 38 | 48,7 | 4,2 | 3,9 | 0,2 | 5 |

| K29-040 PU | 40 | 55,5 | 6,3 | 6 | 0,2 | 6 |

| K29-040/1 PU | 40 | 50,7 | 4,2 | 3,9 | 0,2 | 5 |

| K29-045 PU | 45 | 60,5 | 6,3 | 6 | 0,2 | 6 |

| K29-045/1 PU | 45 | 55,7 | 4,2 | 3,9 | 0,2 | 5 |

| K29-048 PU | 48 | 63,5 | 6,3 | 6 | 0,2 | 6 |

| K29-050 PU | 50 | 65,5 | 6,3 | 6 | 0,2 | 6 |

| K29-050/1 PU | 50 | 60,7 | 4,2 | 3,9 | 0,2 | 5 |

| K29-055 PU | 55 | 70,5 | 6,3 | 6 | 0,2 | 6 |

| K29-055/1 PU | 55 | 70,1 | 6,3 | 6 | 0,2 | 6 |

| K29-056 PU | 56 | 71.1 | 6.3 | 6 | 0.2 | 6 |

| K29-056/1 PU | 56 | 71,5 | 6,3 | 6 | 0,2 | 6 |

| K29-060 PU | 60 | 75,5 | 6,3 | 6 | 0,2 | 6 |

| K29-060/1 PU | 60 | 75,1 | 6,3 | 6 | 0,2 | 6 |

| K29-063 PU | 63 | 78,5 | 6,3 | 6 | 0,2 | 6 |

| K29-065 PU | 65 | 80,5 | 6,3 | 6 | 0,2 | 6 |

| K29-070 PU | 70 | 85,5 | 6,3 | 6 | 0,2 | 6 |

| K29-070/1 PU | 70 | 85,1 | 6,3 | 6 | 0,2 | 6 |

| K29-075 PU | 75 | 90,5 | 6,3 | 6 | 0,2 | 6 |

| K29-075/1 PU | 75 | 90,1 | 6,3 | 6 | 0,2 | 6 |

| K29-078 PU | 78 | 93,1 | 6,3 | 6 | 0,2 | 6 |

| K29-080 PU | 80 | 95,5 | 6,3 | 6 | 0,2 | 6 |

| K29-085 PU | 85 | 100,5 | 6,3 | 6 | 0,2 | 6 |

| K29-090 PU | 90 | 105,5 | 6,3 | 6 | 0,2 | 6 |

| K29-095 PU | 95 | 110,5 | 6,3 | 6 | 0,2 | 6 |

| K29-100 PU | 100 | 115,5 | 6,3 | 6 | 0,2 | 6 |

| K29-105 PU | 105 | 120,5 | 6,3 | 6 | 0,2 | 6 |

| K29-110 PU | 110 | 125,5 | 6,3 | 6 | 0,2 | 6 |

| K29-115 PU | 115 | 130,5 | 6,3 | 6 | 0,2 | 6 |

| K29-120 PU | 120 | 135,5 | 6,3 | 5.8 | 0,2 | 6 |

| K29-125 PU | 125 | 140,5 | 6,3 | 6 | 0,2 | 6 |

| K29-130 PU | 130 | 145,5 | 6,3 | 6 | 0,2 | 6 |

| K29-140 PU | 140 | 155,5 | 6,3 | 6 | 0,2 | 6 |

| K29-150 PU | 150 | 165,5 | 6,3 | 6 | 0,2 | 6 |

|

||||||||||||||||||||||||

|

K29 is a two piece single acting buffer seal which consists of onespecial designed elastomeric sealing element for to evacuatethe back pressure and one thermoplastic back-up ring. APPLICATION |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

| SURFACE ROUGHNESS | Ra | Rmax | ||||||||||||||||

| Sliding Surface Ød | ≤0.4 μm | ≤3.2 μm | ||||||||||||||||

| Groove Base ØD | ≤1.6 μm | ≤6.3 μm | ||||||||||||||||

| Groove Flanks B | ≤3.2 μm | ≤16 μm | ||||||||||||||||

| Note: It is recommended to have 50% to 90% of the working surface material contact area value. | ||||||||||||||||||

|

INSTALLATION NOTES |

||||||||||||||||||

|

||||||||||||||||||