RodSeal

| KASTAŞ NO | d (f8) | D(H9) | B(-0/+0,2) | n |

|---|---|---|---|---|

| K37-006 | 6 | 14 | 6,5 | 5 |

| K37-012 | 12 | 23 | 7,5 | 5 |

| K37-015 | 15 | 27 | 7 | 5 |

| K37-016 | 16 | 28 | 7,5 | 5 |

| K37-016/1 | 16 | 24 | 7 | 5 |

| K37-018 | 18 | 26 | 6,3 | 5 |

| K37-018/1 | 18 | 28 | 6,3 | 5 |

| K37-018/2 | 18 | 30 | 7,5 | 5 |

| K37-020 | 20 | 30 | 8 | 5 |

| K37-020/1 | 20 | 27 | 6 | 5 |

| K37-020/2 | 20 | 28 | 6,3 | 5 |

| K37-020/3 | 20 | 28 | 7 | 5 |

| K37-020/4 | 20 | 30 | 8,5 | 5 |

| K37-020/5 | 20 | 28 | 5,6 | 5 |

| K37-022 | 22 | 32 | 7,5 | 5 |

| K37-022/1 | 22 | 29 | 5 | 5 |

| K37-022/2 | 22 | 30 | 7 | 5 |

| K37-022/3 | 22 | 32 | 10 | 5 |

| K37-022/4 | 22 | 34 | 9,5 | 5 |

| K37-022/5 | 22 | 35 | 10 | 5 |

| K37-025 | 25 | 38 | 9,5 | 5 |

| K37-025/1 | 25 | 33 | 6 | 5 |

| K37-025/2 | 25 | 35 | 8 | 5 |

| K37-025/3 | 25 | 33 | 6,4 | 5 |

| K37-025/4 | 25 | 35 | 9 | 5 |

| K37-025/5 | 25 | 38 | 10 | 5 |

| K37-025/6 | 25,4 | 38,1 | 10 | 5 |

| K37-025/7 | 25 | 33 | 7 | 5 |

| K37-028 | 28 | 38 | 8 | 5 |

| K37-028/1 | 28 | 41 | 9,5 | 5 |

| K37-028/2 | 28 | 36 | 6,5 | 5 |

| K37-028/3 | 28 | 40 | 9,5 | 5 |

| K37-028/4 | 28 | 41 | 10 | 5 |

| K37-028/5 | 28,57 | 39,68 | 9,25 | 5 |

| K37-030 | 30 | 40 | 10,5 | 5 |

| K37-030/1 | 30 | 38 | 6,5 | 5 |

| K37-030/2 | 30 | 40 | 7 | 5 |

| K37-030/3 | 30 | 40 | 7,5 | 5 |

| K37-030/4 | 30 | 45 | 9 | 5 |

| K37-030/5 | 30 | 50 | 14,5 | 5 |

| K37-031 | 31,75 | 47,62 | 11,6 | 5 |

| K37-032 | 32 | 40 | 9 | 5 |

| K37-032/1 | 32 | 42 | 11 | 5 |

| K37-032/2 | 32 | 45 | 10 | 5 |

| K37-032/3 | 32 | 40 | 5 | 5 |

| K37-034 | 32,92 | 50,8 | 8,5 | 5 |

| K37-035 | 35 | 45 | 10,5 | 5 |

| K37-035/1 | 35 | 50 | 10,5 | 5 |

| K37-035/2 | 35 | 45 | 10 | 5 |

| K37-035/3 | 35 | 50 | 11,5 | 5 |

| K37-035/4 | 35 | 43 | 6 | 5 |

| K37-036 | 36 | 43 | 6,5 | 5 |

| K37-036/1 | 36 | 44 | 6,4 | 5 |

| K37-036/2 | 36 | 46 | 8,5 | 5 |

| K37-036/3 | 36 | 48 | 12 | 5 |

| K37-036/4 | 36 | 48 | 9,5 | 5 |

| K37-038 | 38 | 55 | 10,5 | 5 |

| K37-038/1 | 38,1 | 50,8 | 10 | 5 |

| K37-038/2 | 38,1 | 53,97 | 10,5 | 5 |

| K37-040 | 40 | 50 | 10,5 | 5 |

| K37-040/1 | 40 | 55 | 10,5 | 5 |

| K37-040/2 | 40 | 50 | 11 | 5 |

| K37-040/3 | 40 | 48 | 6,5 | 5 |

| K37-040/4 | 40 | 55 | 11 | 5 |

| K37-040/5 | 40 | 50 | 10 | 5 |

| K37-040/6 | 40 | 50 | 8 | 5 |

| K37-040/7 | 40 | 55 | 8 | 5 |

| K37-040/8 | 40 | 60 | 14,5 | 5 |

| K37-042 | 42 | 52 | 9 | 5 |

| K37-044 | 44,45 | 53,97 | 7,14 | 5 |

| K37-044/1 | 44,45 | 53,97 | 7,62 | 5 |

| K37-044/2 | 44,45 | 60,32 | 11,6 | 5 |

| K37-045 | 45 | 55 | 10,5 | 5 |

| K37-045/1 | 45 | 60 | 10,5 | 5 |

| K37-045/2 | 45 | 55 | 11 | 5 |

| K37-045/3 | 45 | 55 | 8 | 5 |

| K37-045/4 | 45 | 55 | 7,5 | 5 |

| K37-045/5 | 45 | 57 | 10 | 5 |

| K37-045/6 | 45 | 65 | 14,5 | 5 |

| K37-045/7 | 45 | 53 | 8,5 | 5 |

| K37-045/8 | 45 | 60 | 10 | 5 |

| K37-050 | 50 | 65 | 10,5 | 5 |

| K37-050/1 | 50 | 62 | 10 | 5 |

| K37-050/10 | 50 | 63 | 12 | 5 |

| K37-050/2 | 50 | 60 | 10,5 | 5 |

| K37-050/3 | 50 | 60 | 10 | 5 |

| K37-050/4 | 50 | 65 | 11 | 5 |

| K37-050/5 | 50 | 62 | 8 | 5 |

| K37-050/6 | 50 | 70 | 14 | 5 |

| K37-050/7 | 50 | 60 | 7,5 | 5 |

| K37-050/8 | 50 | 60 | 8 | 5 |

| K37-050/9 | 50 | 70 | 14,5 | 5 |

| K37-054 | 54 | 66 | 9,5 | 5 |

| K37-055 | 55 | 65 | 10,5 | 5 |

| K37-055/1 | 55 | 65 | 12 | 5 |

| K37-055/2 | 55 | 65 | 11 | 5 |

| K37-055/3 | 55 | 75 | 14 | 5 |

| K37-055/4 | 55 | 65 | 8 | 5 |

| K37-055/5 | 55 | 70 | 10,5 | 5 |

| K37-055/6 | 55 | 75 | 14,5 | 5 |

| K37-056 | 56 | 66 | 10,5 | 5 |

| K37-056/1 | 56 | 71 | 10,5 | 5 |

| K37-056/2 | 56 | 76 | 14,5 | 5 |

| K37-057 | 57,15 | 69,85 | 10 | 5 |

| K37-060 | 60 | 70 | 10,5 | 5 |

| K37-060/1 | 60 | 70 | 12,5 | 5 |

| K37-060/11 | 60 | 80 | 14,5 | 5 |

| K37-060/2 | 60 | 80 | 14 | 5 |

| K37-060/3 | 60 | 75 | 13 | 5 |

| K37-060/4 | 60 | 75 | 12,5 | 5 |

| K37-060/5 | 60 | 69,5 | 7 | 5 |

| K37-060/6 | 60 | 70 | 11 | 5 |

| K37-060/7 | 60 | 70 | 8 | 5 |

| K37-060/8 | 60 | 70 | 13 | 5 |

| K37-060/9 | 60 | 72 | 10 | 5 |

| K37-063 | 63 | 71 | 9 | 5 |

| K37-063/1 | 63 | 75 | 11 | 5 |

| K37-063/2 | 63 | 78 | 12,5 | 5 |

| K37-063/3 | 63,5 | 83 | 14,5 | 5 |

| K37-063/4 | 63,5 | 82,55 | 14,28 | 5 |

| K37-063/5 | 63,5 | 76,2 | 8,5 | 5 |

| K37-063/6 | 63,5 | 77,78 | 11,5 | 5 |

| K37-065 | 65 | 80 | 12,5 | 5 |

| K37-065/1 | 65 | 75 | 12,5 | 5 |

| K37-065/2 | 65 | 75 | 13,5 | 5 |

| K37-065/3 | 65 | 77 | 9,6 | 5 |

| K37-065/4 | 65 | 80 | 11,5 | 5 |

| K37-070 | 70 | 80 | 12,5 | 5 |

| K37-070/1 | 70 | 85 | 12 | 5 |

| K37-070/2 | 70 | 85 | 12,5 | 5 |

| K37-070/3 | 70 | 90 | 14 | 5 |

| K37-070/4 | 70 | 80 | 8 | 5 |

| K37-070/5 | 70 | 80 | 13 | 5 |

| K37-070/6 | 70 | 82 | 10,5 | 5 |

| K37-070/7 | 70 | 84 | 12,5 | 5 |

| K37-070/8 | 70 | 90 | 12 | 5 |

| K37-075 | 75 | 85 | 12,5 | 5 |

| K37-075/1 | 75 | 90 | 11 | 5 |

| K37-075/2 | 75 | 85 | 11 | 5 |

| K37-075/3 | 75 | 90 | 11,5 | 5 |

| K37-075/4 | 75 | 90 | 12,8 | 5 |

| K37-075/5 | 75 | 95 | 14,5 | 5 |

| K37-075/6 | 75 | 88 | 12,5 | 5 |

| K37-080 | 80 | 90 | 12,5 | 5 |

| K37-080/1 | 80 | 100 | 12,5 | 5 |

| K37-080/2 | 80 | 100 | 14 | 5 |

| K37-080/3 | 80 | 95 | 12 | 5 |

| K37-080/4 | 80 | 93 | 14,5 | 5 |

| K37-080/5 | 80 | 96 | 10,5 | 5 |

| K37-080/6 | 80 | 100 | 12 | 5 |

| K37-080/7 | 80 | 100 | 14,5 | 5 |

| K37-080/8 | 80 | 95 | 10 | 5 |

| K37-085 | 85 | 100 | 12,5 | 5 |

| K37-085/1 | 85 | 95 | 8 | 5 |

| K37-085/2 | 85 | 100 | 12 | 5 |

| K37-085/3 | 85 | 105 | 14,5 | 5 |

| K37-088 | 88,9 | 114,3 | 19,5 | 5 |

| K37-090 | 90 | 105 | 12,5 | 5 |

| K37-090/1 | 90 | 110 | 12,5 | 5 |

| K37-090/2 | 90 | 105 | 9,5 | 5 |

| K37-090/4 | 90 | 106,5 | 10,8 | 5 |

| K37-095 | 95 | 106,2 | 11 | 5 |

| K37-095/1 | 95 | 112 | 12 | 5 |

| K37-095/2 | 95 | 115 | 14,5 | 5 |

| K37-095/3 | 95 | 110 | 12 | 7 |

| K37-095/4 | 95 | 115 | 12 | 5 |

| K37-095/5 | 95 | 107 | 12,5 | 5 |

| K37-100 | 100 | 115 | 12,5 | 7 |

| K37-100/1 | 100 | 120 | 14 | 7 |

| K37-100/2 | 100 | 125 | 19 | 7 |

| K37-100/3 | 100 | 120 | 24,5 | 7 |

| K37-100/4 | 100 | 115 | 11,5 | 7 |

| K37-100/5 | 100 | 120 | 12 | 7 |

| K37-100/6 | 100 | 120 | 14,5 | 7 |

| K37-100/7 | 100 | 113 | 13,5 | 7 |

| K37-105 | 105 | 115 | 11 | 7 |

| K37-105/1 | 105 | 125 | 12,5 | 7 |

| K37-110 | 110 | 130 | 12,5 | 7 |

| K37-110/1 | 110 | 125 | 12 | 7 |

| K37-110/2 | 110 | 135 | 15,5 | 7 |

| K37-115 | 115 | 135 | 16 | 7 |

| K37-120 | 120 | 130 | 10,5 | 7 |

| K37-120/1 | 120 | 132,7 | 10 | 7 |

| K37-120/2 | 120 | 135 | 12,5 | 7 |

| K37-120/3 | 120 | 140 | 12,5 | 7 |

| K37-120/4 | 120 | 145 | 18,8 | 7 |

| K37-125 | 125 | 150 | 14 | 7 |

| K37-125/1 | 125 | 150 | 14,5 | 7 |

| K37-130 | 130 | 145 | 13 | 7 |

| K37-130/1 | 130 | 145 | 15 | 7 |

| K37-130/2 | 130 | 150 | 16 | 7 |

| K37-135 | 135 | 150 | 14 | 7 |

| K37-135/1 | 135 | 160 | 14 | 7 |

| K37-140 | 140 | 160 | 12 | 7 |

| K37-140/1 | 140 | 155 | 13 | 7 |

| K37-140/2 | 140 | 160 | 14,5 | 7 |

| K37-140/3 | 140 | 160 | 12,5 | 7 |

| K37-140/4 | 140 | 170 | 22,8 | 7 |

| K37-145 | 145 | 157,7 | 10 | 7 |

| K37-150 | 150 | 170 | 14 | 7 |

| K37-150/1 | 150 | 170 | 14,5 | 7 |

| K37-160 | 160 | 175 | 16 | 7 |

| K37-160/1 | 160 | 180 | 14,5 | 7 |

| K37-175 | 175 | 200 | 23 | 7 |

| K37-175 | 175 | 200 | 23 | 7 |

| K37-180 | 180 | 200 | 14,5 | 7 |

| K37-180 | 180 | 200 | 14,5 | 7 |

| K37-180/1 | 180 | 210 | 20,5 | 7 |

| K37-180/1 | 180 | 210 | 20,5 | 7 |

| K37-190 | 190 | 210 | 14,5 | 7 |

| K37-190 | 190 | 210 | 14,5 | 7 |

| K37-198 | 198 | 208 | 12 | 7 |

| K37-198 | 198 | 208 | 12 | 7 |

| K37-200 | 200 | 220 | 14,5 | 10 |

| K37-200 | 200 | 220 | 14,5 | 10 |

| K37-210 | 210 | 240 | 22,5 | 10 |

| K37-210 | 210 | 240 | 22,5 | 10 |

| K37-220 | 220 | 250 | 20,5 | 10 |

| K37-220 | 220 | 250 | 20,5 | 10 |

| K37-230 | 230 | 260 | 20,5 | 10 |

| K37-230 | 230 | 260 | 20,5 | 10 |

|

||||||||||||||||||||||||

|

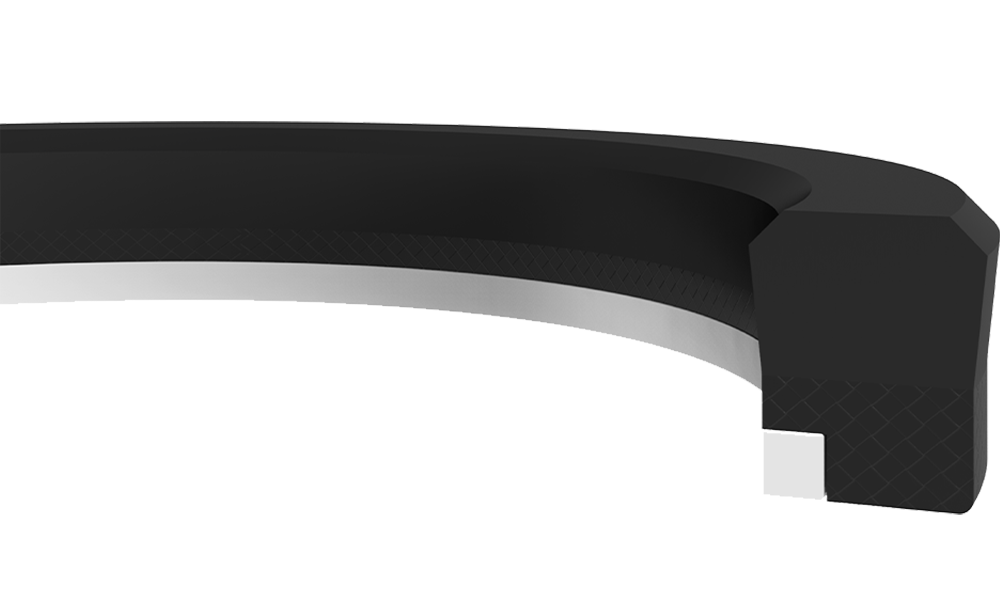

K37 is a two piece single acting rod seal which consists of areinforced cotton fabric and nitrile rubber vulcanized togetherforming an integral sealing element and one thermoplasticback-up ring. PRODUCT ADVANTAGES APPLICATION |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

| SURFACE ROUGHNESS | Ra | Rmax |

| Sliding Surface Ød | ≤0.4 μm | ≤3.2 μm |

| Groove Base ØD | ≤1.8 μm | ≤6.3 μm |

| Groove Flanks B | ≤3.2 μm | ≤16 μm |

| Note: It is recommended to have 50% to 90% of the working surface material contact area value. | ||

|

INSTALLATION NOTES |

||

| PERMISSIBLE SEALING GAP | |

| Pressure (Bar) | Smax (mm) |

| 150 | 0.4 |

| 250 | 0.1 |

| 400 | 0.2 |

Note: The largest sealing gap value occurring on the non-pressurized side of the seal does have a vital importance for the function of the seal and in this respect it is quite important to use the S value lower than the above indicated numbers.