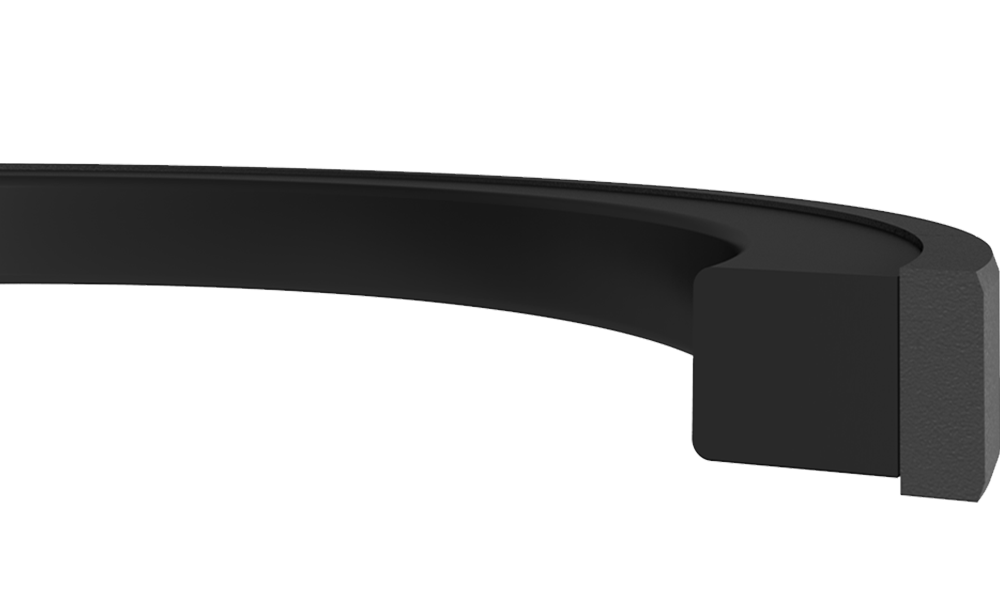

Piston Seal

| KAŞTAŞ NO | D(H9) | d(h9) | B(-0/+0.2) | r | n |

|---|---|---|---|---|---|

| K501-050 | 50 | 39 | 4.2 | 1 | 6 |

| K501-060 | 60 | 44.5 | 6.3 | 1.3 | 8 |

| K501-063 | 63 | 47,5 | 6,3 | 1,3 | 8 |

| K501-075 | 75 | 54 | 8,1 | 1,8 | 10,5 |

| K501-080 | 80 | 64,5 | 6,3 | 1,3 | 6 |

| K501-085 | 85 | 69,5 | 6,3 | 1,3 | 6 |

| K501-090 | 90 | 74,5 | 6,3 | 1,3 | 6 |

| K501-090/1 | 90 | 69 | 8.1 | 1.8 | 10.5 |

| K501-095 | 95 | 74 | 8,1 | 1,8 | 10,5 |

| K501-100 | 100 | 84,5 | 6,3 | 1,3 | 6 |

| K501-100/1 | 100 | 79 | 8.1 | 1.8 | 10.5 |

| K501-105 | 105 | 84 | 8,1 | 1,8 | 10,5 |

| K501-105/1 | 105 | 89,5 | 6,3 | 1,3 | 6 |

| K501-110 | 110 | 94,5 | 6,3 | 1,3 | 6 |

| K501-115 | 115 | 94 | 8,1 | 1,8 | 10,5 |

| K501-120 | 120 | 99 | 8,1 | 1,8 | 10,5 |

| K501-125 | 125 | 104 | 8,1 | 1,8 | 10,5 |

| K501-125/1 | 125 | 110 | 6,3 | 1,3 | 10,5 |

| K501-130 | 130 | 109 | 8,1 | 1,8 | 10,5 |

| K501-135 | 135 | 114 | 8,1 | 1,8 | 10,5 |

| K501-140 | 140 | 119 | 8,1 | 1,8 | 10,5 |

| K501-145 | 145 | 124 | 8,1 | 1,8 | 10,5 |

| K501-150 | 150 | 129 | 8,1 | 1,8 | 10,5 |

| K501-160 | 160 | 139 | 8,1 | 1,8 | 10,5 |

| K501-165 | 165 | 144 | 8,1 | 1,8 | 10,5 |

| K501-170 | 170 | 149 | 8,1 | 1,8 | 10,5 |

| K501-175 | 175 | 154 | 8,1 | 1,8 | 10,5 |

| K501-180 | 180 | 159 | 8,1 | 1,8 | 10,5 |

| K501-185 | 185 | 164 | 8,1 | 1,8 | 10,5 |

| K501-190 | 190 | 169 | 8,1 | 1,8 | 10,5 |

| K501-200 | 200 | 179 | 8,1 | 1,8 | 10,5 |

| K501-210 | 210 | 189 | 8,1 | 1,8 | 10,5 |

| K501-215 | 215 | 194 | 8,1 | 1,8 | 10,5 |

| K501-220 | 220 | 199 | 8,1 | 1,8 | 10,5 |

| K501-225 | 225 | 204 | 8,1 | 1,8 | 10,5 |

| K501-230 | 230 | 209 | 8,1 | 1,8 | 10,5 |

| K501-250 | 250 | 229 | 8,1 | 1,8 | 10,5 |

|

||||||||||||||||||||||||

|

K501 is a two piece double acting piston seal consisting of a thermoplastic sealing element and one energizer elastomer ring. ADVANTAGES APPLICATION |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

| SURFACE ROUGHNESS | Ra | Rmax |

| Sliding Surface Ød | ≤0.4 μm | ≤4.0μm |

| Groove Base ØD | ≤1.6 μm | ≤6.3μm |

| Groove Flanks S1 | ≤3.2 μm | ≤16 μm |

| Note: It is recommended to have 50% to 90% of the working surface material contact area value. | ||

|

INSTALLATION NOTES |

||

| PERMISSIBLE SEALING GAP | |

| B (mm) | Smax ( mm ) |

| 4.2 | 0.35 |

| 6.3 | 0.50 |

| 8 | 0.60 |

| Note:All the above mentioned “S” values are maximum and it’s vital to use lower values for system security. | |