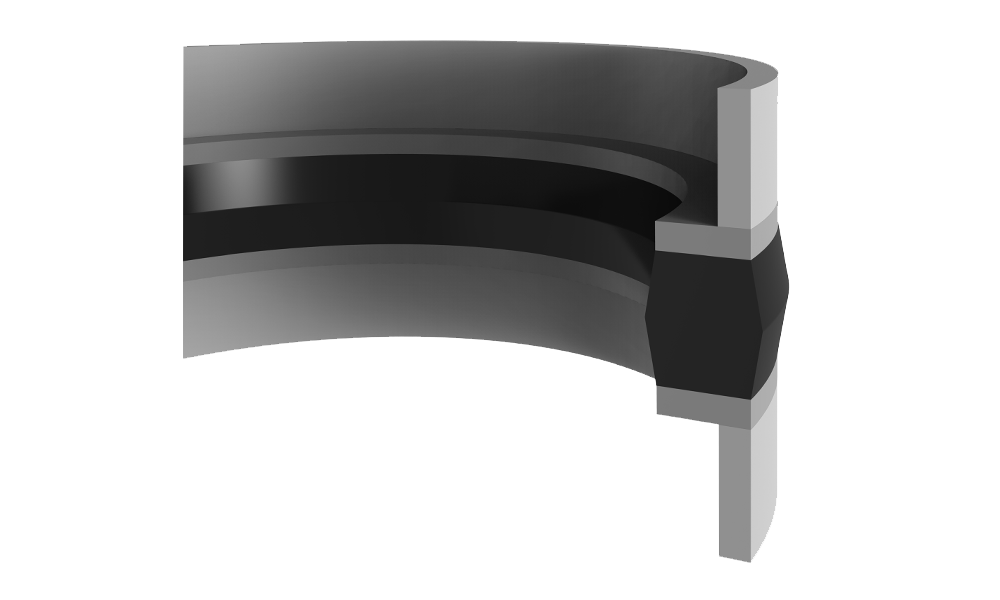

Compact Piston Seal

| KASTAŞ NO | D(H9) | d(h10) | ds(h8) | d1(+0.0/-0.1) | B(+0.2/-0.0) | s(+0.1/-0.0) | n |

|---|---|---|---|---|---|---|---|

| K503-101,6-82,55 | 101.6 | 82.55 | 95.83 | 99.57 | 19.43 | 6.35 | 5 |

| K503-101,6-82,55/1 | 101.6 | 82.55 | 95.07 | 99.57 | 19.43 | 12.7 | 5 |

| K503-107,95-88,9 | 107.95 | 88.9 | 101.42 | 105.92 | 19.43 | 12.7 | 5 |

| K503-114,3-95,25 | 114.3 | 95.25 | 107.72 | 112.27 | 19.43 | 12.7 | 5 |

| K503-120,65-101,6 | 120.65 | 101.6 | 114.07 | 118.68 | 19.43 | 12.7 | 5 |

| K503-127-107,95 | 127 | 107.95 | 120.42 | 124.97 | 19.43 | 12.7 | 5 |

| K503-139,7-120,65 | 139.7 | 120.65 | 133.12 | 137.67 | 19.43 | 12.7 | 5 |

| K503-152,4-133,35 | 152.4 | 133.35 | 145.82 | 150.37 | 19.43 | 12.7 | 5 |

| K503-177,8-158,75 | 177.8 | 158.75 | 171.22 | 175.77 | 19.43 | 12.7 | 5 |

| K503-203,2-184,15 | 203.2 | 184.15 | 196.62 | 201.17 | 19.43 | 12.7 | 5 |

| K503-28,57-19,05 | 28.57 | 19.05 | 23.8 | 27.05 | 11.1 | 6.35 | 2.5 |

| K503-31,75-22,22 | 31.75 | 22.22 | 26.97 | 30.22 | 11.1 | 6.35 | 2.5 |

| K503-34,92-25,4 | 34.92 | 25.4 | 30.15 | 33.4 | 11.1 | 6.35 | 2.5 |

| K503-38,1-28,57 | 38.1 | 28.57 | 33.55 | 36.57 | 11.1 | 6.35 | 2.5 |

| K503-38,1-28,57/1 | 38.1 | 28.57 | 33.32 | 36.57 | 11.1 | 9.52 | 2.5 |

| K503-41,27-31,75 | 41.27 | 31.75 | 36.47 | 39.75 | 11.1 | 9.52 | 2.5 |

| K503-44,45-34,92 | 44.45 | 34.92 | 39.65 | 42.92 | 11.1 | 9.52 | 2.5 |

| K503-47,62-38,1 | 47.62 | 38.1 | 42.82 | 46.1 | 11.1 | 9.52 | 2.5 |

| K503-50,8-38,1 | 50.8 | 38.1 | 46.25 | 49.28 | 14.52 | 6.35 | 3.5 |

| K503-50,8-38,1/1 | 50.8 | 38.1 | 46 | 49.28 | 14.52 | 9.52 | 3.5 |

| K503-57,15-44,45 | 57.15 | 44.45 | 52.35 | 55.63 | 14.52 | 9.52 | 3.5 |

| K503-63,5-50,8 | 63.5 | 50.8 | 58.95 | 61.98 | 14.52 | 6.35 | 3.5 |

| K503-63,5-50,8/1 | 63.5 | 50.8 | 58.7 | 61.98 | 14.52 | 9.52 | 3.5 |

| K503-69,85-57,15 | 69.75 | 57.15 | 65 | 68.33 | 14.52 | 9.52 | 3.5 |

| K503-76,1-63,5 | 76.2 | 63.5 | 70.46 | 74.68 | 14.52 | 6.35 | 3.5 |

| K503-76,1-63,5/1 | 76.2 | 63.5 | 71.35 | 74.68 | 14.52 | 9.52 | 3.5 |

| K503-82,55-69,85 | 82.55 | 69.85 | 77.7 | 81.03 | 14.52 | 9.52 | 3.5 |

| K503-88,9-76,2 | 88.9 | 76.2 | 83.16 | 87.38 | 14.52 | 6.35 | 3.5 |

| K503-88,9-76,2/1 | 88.9 | 76.2 | 84.05 | 87.38 | 14.52 | 9.52 | 3.5 |

| K503-95,25-82,55 | 95.25 | 82.55 | 88.67 | 93.22 | 14.52 | 12.7 | 3.5 |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||