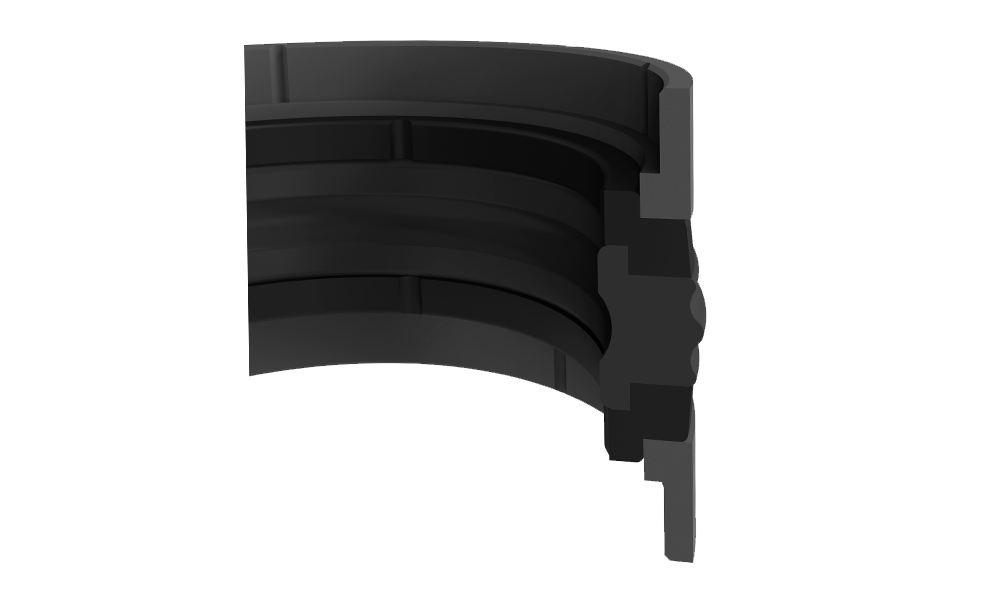

Compact Piston Seal

| KASTAŞ NO | D(H8) | d(h9) | B(+0,2) | ds(h8) | d1(±0,1) | s(+0,2) | n |

|---|---|---|---|---|---|---|---|

| K518 025-016 | 25 | 16 | 13,5 | 22 | 24 | 2,1 | 4 |

| K518 032-022 | 32 | 22 | 16,4 | 28,5 | 30,5 | 6,35 | 4 |

| K518 035-025 | 35 | 25 | 16,4 | 31,4 | 33,5 | 6,35 | 4 |

| K518 040-030 | 40 | 30 | 16,4 | 35,4 | 38,5 | 6,35 | 4 |

| K518 040-030/1 | 40 | 30 | 12,5 | 37 | 39 | 4 | 4 |

| K518 040-032 | 40 | 32 | 15,5 | 36 | 39,4 | 3,2 | 4 |

| K518 040-032/1 | 40 | 32 | 10 | 37 | 39 | 4 | 4 |

| K518 044,4-028,57 | 44,45 | 28,57 | 19,05 | 39,85 | 43,12 | 6,35 | 5 |

| K518 045-029 | 45 | 29 | 18,4 | 40,4 | 43,5 | 6,35 | 5 |

| K518 045-035 | 45 | 35 | 16,4 | 40,4 | 43,5 | 6,35 | 4 |

| K518 050,8-34,92 | 50,8 | 34,92 | 19,05 | 46,22 | 49,48 | 6,35 | 5 |

| K518 050-034 | 50 | 34 | 20,5 | 46 | 49 | 3,1 | 5 |

| K518 050-034/1 | 50 | 34 | 18,4 | 45,41 | 48,66 | 6,35 | 5 |

| K518 050-038 | 50 | 38 | 20,5 | 46 | 49,4 | 4,2 | 4 |

| K518 055-039 | 55 | 39 | 20,5 | 51 | 54 | 3,1 | 5 |

| K518 055-039/1 | 55 | 39 | 18,4 | 50,37 | 53,65 | 6,35 | 5 |

| K518 055-045 | 55 | 45 | 12,5 | 52 | 54 | 4 | 4 |

| K518 060,32-44,45 | 60,32 | 44,45 | 19,05 | 55,72 | 58,98 | 6,35 | 5 |

| K518 060-044 | 60 | 44 | 20,2 | 56 | 59 | 3,1 | 5 |

| K518 060-044/1 | 60 | 44 | 18,4 | 55,39 | 58,65 | 6,35 | 5 |

| K518 060-048 | 60 | 48 | 20,5 | 56 | 59,4 | 4,2 | 4 |

| K518 063-047 | 63 | 47 | 20,5 | 59 | 62 | 3,1 | 5 |

| K518 063-047/1 | 63 | 47 | 18,4 | 58,39 | 61,63 | 6,35 | 5 |

| K518 063-051 | 63 | 51 | 20,5 | 59 | 62,4 | 4,2 | 4 |

| K518 065-049 | 65 | 49 | 20,5 | 61 | 64 | 3,1 | 5 |

| K518 065-050 | 65 | 50 | 18,4 | 60,41 | 63,64 | 6,35 | 5 |

| K518 066,67-50,80 | 66,67 | 50,8 | 19,05 | 62,09 | 65,27 | 6,35 | 5 |

| K518 070-050 | 70 | 50 | 22,4 | 64,18 | 68,34 | 6,35 | 6 |

| K518 070-054 | 70 | 54 | 20,5 | 66 | 69 | 3,1 | 5 |

| K518 075-055 | 75 | 55 | 22,4 | 69,2 | 73,3 | 6,35 | 6 |

| K518 075-059 | 75 | 59 | 20,5 | 71 | 74 | 3,1 | 5 |

| K518 080-060 | 80 | 60 | 22,4 | 74,15 | 78,3 | 6,35 | 6 |

| K518 080-062 | 80 | 62 | 22,5 | 76 | 79 | 3,6 | 5 |

| K518 080-066 | 80 | 66 | 22,4 | 76 | 79,4 | 5,2 | 5 |

| K518 085-065 | 85 | 65 | 22,4 | 79,15 | 83,3 | 6,35 | 6 |

| K518 090-070 | 90 | 70 | 22,4 | 84,15 | 88,3 | 6,35 | 6 |

| K518 090-076 | 90 | 76 | 22,4 | 86 | 89,4 | 5,2 | 5 |

| K518 095-075 | 95 | 75 | 22,4 | 89,15 | 93,31 | 6,35 | 6 |

| K518 100-075 | 100 | 75 | 22,4 | 93,13 | 98 | 6,35 | 6 |

| K518 100-086 | 100 | 86 | 22,4 | 96 | 99,4 | 5,2 | 5 |

| K518 110-085 | 110 | 85 | 22,4 | 103,1 | 108 | 6,35 | 6 |

| K518 110-096 | 110 | 96 | 22,4 | 106 | 109,4 | 5,2 | 5 |

| K518 115-090 | 115 | 90 | 22,4 | 108,1 | 113,02 | 6,35 | 6 |

| K518 115-101 | 115 | 101 | 22,4 | 111 | 114,4 | 5,2 | 5 |

| K518 120-095 | 120 | 95 | 22,4 | 113,1 | 118 | 6,35 | 6 |

| K518 120-106 | 120 | 106 | 22,4 | 116 | 119,4 | 5,2 | 5 |

| K518 125-100 | 125 | 100 | 25,4 | 118,1 | 123 | 6,35 | 6 |

| K518 130-105 | 130 | 105 | 25,4 | 123,1 | 128 | 6,35 | 6 |

| K518 130-105/1 | 130 | 105 | 25,4 | 123,1 | 128 | 9,52 | 6 |

| K518 135-110 | 135 | 110 | 25,4 | 127,6 | 132,5 | 9,52 | 6 |

| K518 140-115/1 | 140 | 115 | 25,4 | 132,6 | 137,5 | 9,52 | 6 |

| K518 140-115/2 | 140 | 115 | 25,4 | 133 | 138 | 6,35 | 6 |

| K518 140-118 | 140 | 118 | 26,5 | 136 | 139 | 5,1 | 6 |

| K518 150-125 | 150 | 125 | 25,4 | 142,6 | 147,5 | 9,5 | 6 |

| K518 150-128 | 150 | 128 | 26,5 | 146 | 149 | 5,1 | 6 |

| K518 160-130 | 160 | 130 | 25,4 | 153 | 157,5 | 6,35 | 7 |

| K518 160-135 | 160 | 135 | 25,4 | 152,6 | 157,5 | 9,52 | 6 |

| K518 160-143 | 160 | 143 | 26,5 | 156 | 159,4 | 7,2 | 5 |

| K518 165-143 | 165 | 143 | 26,5 | 161 | 163,5 | 5,25 | 4 |

| K518 170-148 | 170 | 148 | 26,5 | 166 | 169 | 5,1 | 6 |

| K518 180-150 | 180 | 150 | 35,4 | 172,94 | 177,87 | 6,35 | 7 |

| K518 180-155 | 180 | 155 | 25,4 | 171,72 | 177,1 | 12,7 | 6 |

| K518 180-158 | 180 | 158 | 26,5 | 176 | 179 | 5,1 | 6 |

| K518 180-163 | 180 | 163 | 26,5 | 176 | 179,4 | 7,2 | 5 |

| K518 190-165 | 190 | 165 | 25,4 | 181,72 | 187,05 | 12,7 | 6 |

| K518 200-175 | 200 | 175 | 31,5 | 196 | 199 | 6,6 | 6 |

| K518 200-175/1 | 200 | 175 | 25,4 | 191,62 | 197 | 12,7 | 6 |

| K518 200-180 | 200 | 180 | 31,5 | 196 | 199,4 | 9,2 | 6 |

| K518 210-185 | 210 | 185 | 25,4 | 201,62 | 207 | 12,7 | 6 |

| K518 220-200 | 220 | 200 | 31,5 | 216 | 219,4 | 9,2 | 6 |

| K518 250-225 | 250 | 225 | 25,4 | 241,62 | 247 | 12,7 | 6 |

| K518 250-230 | 250 | 230 | 31,5 | 246 | 249,4 | 9,2 | 6 |

|

||||||||||||||||||||||||

|

K518 is a five piece double acting compact seal which consists of one elastomeric nitrile rubber sealing element , two polyester elastomer back-up rings on both sides to prevent extrusion into the sealing gap and two special profiled guide rings produced from thermoplastic to absorb transverse forces. PRODUCT ADVANTAGES•Superior radial load bearing capacity •Economic sealing and guiding solution •Simple groove design , one-piece piston possible •Long service life •Simple snap installation APPLICATION Mobile hydraulics , back-hoe loaders , fork-lift trucks , agricultural machinery , standard cylinders. |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||