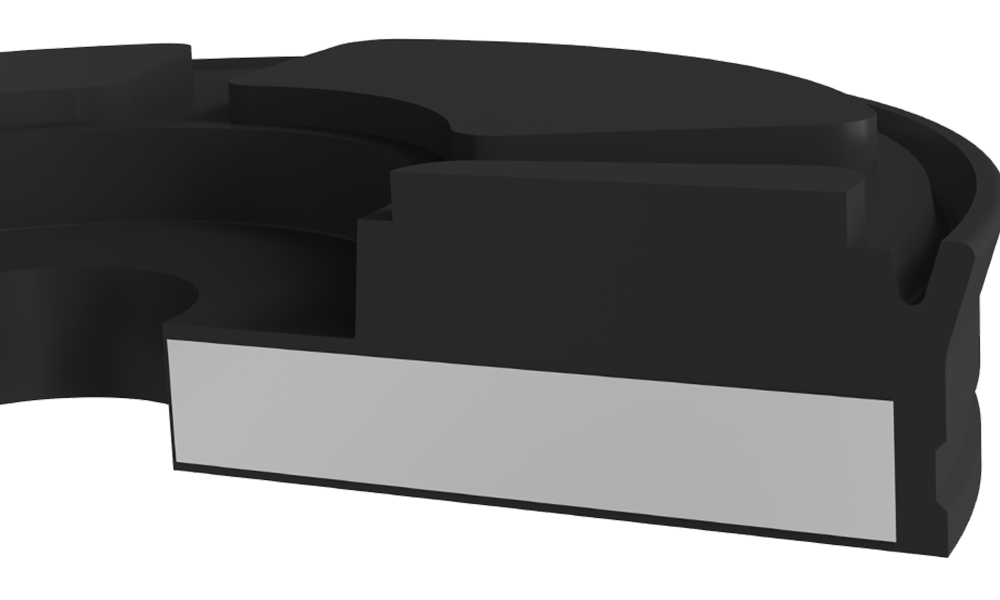

Pneumatic Piston Seal

| KASTAŞ NO | D (H11) | d (h10) | B | d1 (±0,2) | b | s | h |

|---|---|---|---|---|---|---|---|

| K55-016 | 16 | 4,5 | 4,4 | 6,9 | 3,4 | 2 | 2,3 |

| K55-020 | 20 | 6 | 5,5 | 9,4 | 4,4 | 2,5 | 2,8 |

| K55-025 | 25 | 7 | 6,4 | 10,8 | 5,4 | 3 | 3,5 |

| K55-032 | 32 | 8 | 7,5 | 12,5 | 6 | 3 | 3,5 |

| K55-040 | 40 | 8 | 8,5 | 17 | 7 | 4 | 4,5 |

| K55-050 | 50 | 10 | 10 | 26 | 8 | 4 | 4,5 |

| K55-063 | 63 | 12 | 10 | 26 | 8 | 4 | 4,5 |

| K55-080 | 80 | 16 | 11,4 | 30 | 9 | 5 | 5,5 |

| K55-100 | 100 | 20 | 12,9 | 35 | 10,9 | 6 | 6,5 |

|

||||||||||

|

K55 is a single acting complete piston seal which consists of an aluminum plate vulcanized with elastomeric nitrile rubber using special production methods. PRODUCT ADVANTAGES APPLICATION |

||||||||||

|

||||||||||

|

||||||||||

| SURFACE ROUGHNESS | Rmax |

| Sliding Surface Ød | ≤4 μm |

|

INSTALLATION |

|