Pneumatic Piston Seal

| Kastaş No | D (H11) | d1 (f8) | d2 (f8) | B(-0/+0.2) | b | n |

|---|---|---|---|---|---|---|

| K61-035 | 35 | 8 | 16 | 8 | 8 | 4 |

| K61-040 | 40 | 10 | 18 | 8 | 8 | 4 |

| K61-060 | 60 | 12 | 20 | 8 | 8 | 4 |

|

|||||||||||||||

|

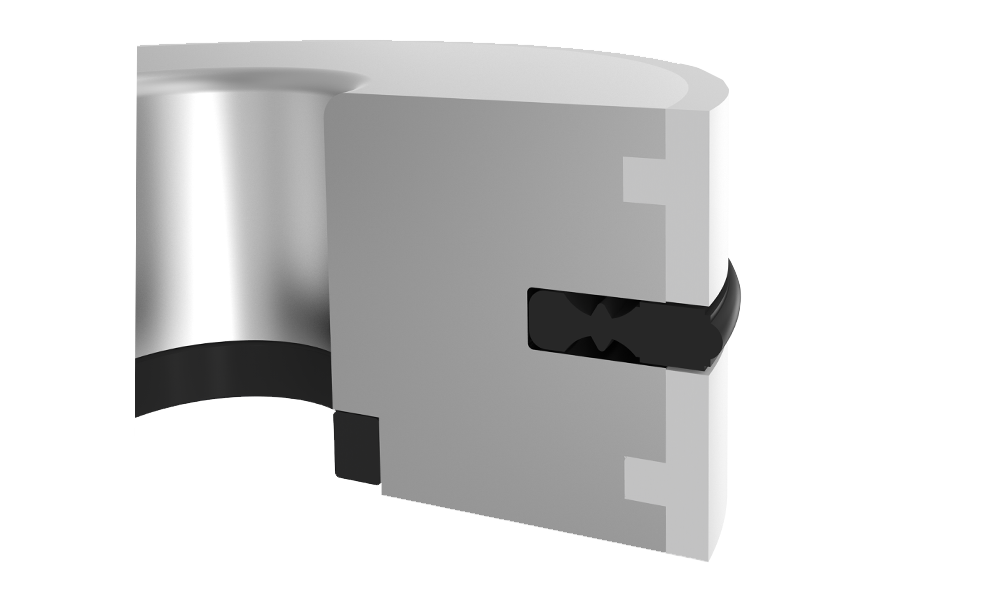

K61 is a double acting pneumatic compact seal which consists of two POM guide rings, one NBR sealing element (dynamic and static) and an aluminium body.

PRODUCT ADVANTAGES APPLICATION |

|||||||||||||||

|

|||||||||||||||

|

|||||||||||||||

| SURFACE ROUGHNESS | Rmax |

| Sliding Surface | ≤4 μm |

|

INSTALLATION K61 is pushed onto the piston rod on the clamping flange towards the rod and fixed by fastening. The nut has to be secured. The sliding surface and the cylinder bore should be oiled with oil that must not go into the reaction with the sealing element during the installation process.

Before installation the sealing element must be oiled with system oil. Pay attention not to deform the sealing element during installation. Chamfer at the cylinder bore must be proper and free of burrs.

|

|