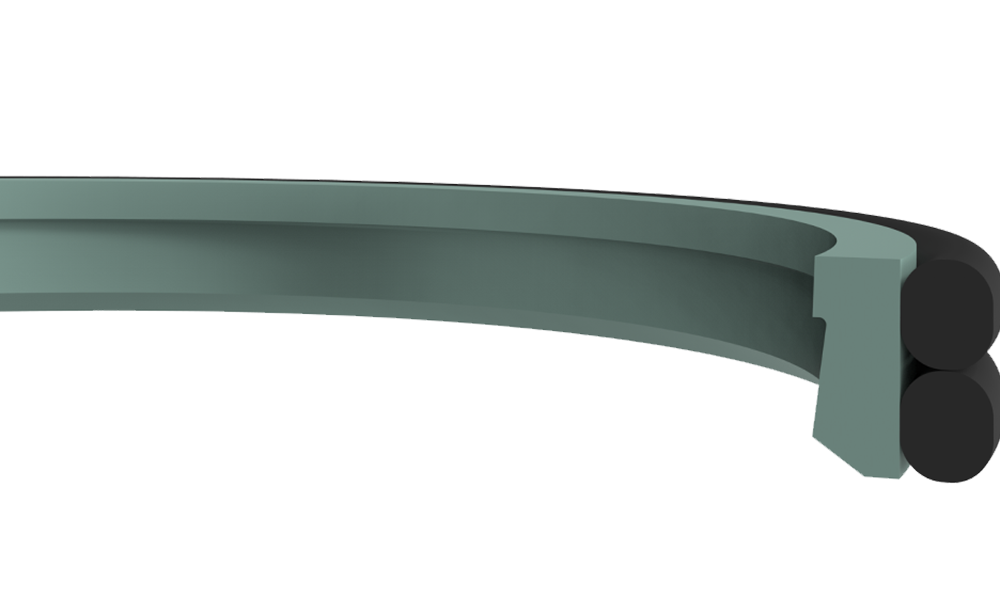

K705

Wiper

| KASTAŞ NO | d(f8) | D(H9) | D1(-0/+0.2) | B(-0/+0.2) | B1 | r | n |

|---|---|---|---|---|---|---|---|

| K705-040 | 40 | 48.8 | 41.5 | 6.3 | 10.3 | 1.2 | 3 |

| K705-045 | 45 | 53.8 | 46.5 | 6.3 | 10.3 | 1.2 | 3 |

| K705-050 | 50 | 58.8 | 51.5 | 6.3 | 10.3 | 1.2 | 3 |

| K705-055 | 55 | 63.8 | 56.5 | 6.3 | 10.3 | 1.2 | 4 |

| K705-056 | 56 | 64.8 | 57.5 | 6.3 | 10.3 | 1.2 | 4 |

| K705-060 | 60 | 68.8 | 61.5 | 6.3 | 10.3 | 1.2 | 4 |

| K705-063 | 63 | 71.8 | 64.5 | 6.3 | 10.3 | 1.2 | 4 |

| K705-065 | 65 | 73.8 | 66.5 | 6.3 | 10.3 | 1.2 | 4 |

| K705-070 | 70 | 82.2 | 72 | 8.1 | 12.1 | 2 | 4 |

| K705-075 | 75 | 87.2 | 77 | 8.1 | 12.1 | 2 | 4 |

| K705-080 | 80 | 92.2 | 82 | 8.1 | 12.1 | 2 | 4 |

| K705-085 | 85 | 97.2 | 87 | 8.1 | 12.1 | 2 | 4 |

| K705-090 | 90 | 102.2 | 92 | 8.1 | 12.1 | 2 | 4 |

| K705-100 | 100 | 112.2 | 102 | 8.1 | 12.1 | 2 | 4 |

| K705-105 | 105 | 117.2 | 107 | 8.1 | 12.1 | 2 | 4 |

| K705-110 | 110 | 122.2 | 112 | 8.1 | 12.1 | 2 | 4 |

| K705-115 | 115 | 127.2 | 117 | 8.1 | 12.1 | 2 | 4 |

| K705-120 | 120 | 132.1 | 122 | 8.1 | 12.1 | 2 | 4 |

| K705-125 | 125 | 137.2 | 127 | 8.1 | 12.1 | 2 | 6 |

| K705-130 | 130 | 142.2 | 132 | 8.1 | 12.1 | 2 | 6 |

| K705-135 | 135 | 147.2 | 137 | 8.1 | 12.1 | 2 | 6 |

| K705-140 | 140 | 156 | 142 | 11.5 | 15.5 | 2 | 6 |

| K705-150 | 150 | 166 | 152 | 11.5 | 15.5 | 2 | 6 |

| K705-155 | 155 | 171 | 157 | 11.5 | 15.5 | 2 | 6 |

| K705-160 | 160 | 176 | 162 | 11.5 | 15.5 | 2 | 6 |

| K705-170 | 170 | 186 | 172 | 11.5 | 15.5 | 2 | 6 |

| K705-180 | 180 | 196 | 182 | 11.5 | 15.5 | 2 | 6 |

| K705-190 | 190 | 206 | 192 | 11.5 | 15.5 | 2 | 6 |

| K705-200 | 200 | 216 | 202 | 11.5 | 15.5 | 2 | 6 |

| K705-220 | 220 | 236 | 222 | 11.5 | 15.5 | 2 | 6 |

| K705-230 | 230 | 246 | 232 | 11,5 | 15,5 | 2 | 8 |

| K705-240 | 240 | 256 | 242 | 11.5 | 15.5 | 2 | 8 |

| K705-250 | 250 | 266 | 252 | 11.5 | 15.5 | 2 | 8 |

| K705-265/1 | 265 | 281 | 267 | 11,5 | 15,5 | 2 | 8 |

| K705-290 | 290 | 306 | 292 | 11.5 | 15.5 | 2 | 8 |

| K705-300 | 300 | 316 | 302 | 11.5 | 15.5 | 2 | 8 |

| K705-310 | 310 | 326 | 312 | 11,5 | 15,5 | 2 | 8 |

| K705-320 | 320 | 336 | 322 | 11,5 | 15,5 | 2 | 8 |

| K705-330 | 330 | 346 | 332 | 11.5 | 15.5 | 2 | 8 |

| K705-370 | 370 | 386 | 372 | 11.5 | 15.5 | 2 | 8 |

| K705-380 | 380 | 396 | 382 | 11.5 | 15.5 | 2 | 8 |

| K705-570 | 570 | 594 | 572.5 | 15.5 | 19.5 | 2 | 8 |

|

|||||||||

|

K705 is a three piece single acting wiper which consists of one special mixture PTFE profile ring and two o-rings as energizers. K705 ensures that foreign particles are not introduced into the hydraulic systems , avoiding wear and damage to all the internal components including seals. PRODUCT ADVANTAGES•Low friction •Free of stick-slip •High sliding speed •Wide range of temperature and chemicals depending on the elastomer material APPLICATION •Mobile hydraulics , aluminium injection machines and industrial machinery , control and regulation equipment |

|||||||||

|

|||||||||

Note: The above data are maximum values and cannot be used at the same time. For HFA HFB HFC used applications , special filled PTFE materials are recommended. Resistance in low temperature and high temperature applications can be improved by alternate elastomer compounds. |

|||||||||

| SURFACE ROUGHNESS | Ra | Rmax |

| Sliding Surface Ød | ≤0.2 μm | ≤2.0μm |

| Groove Base ØD | ≤1.6μm | ≤6.3μm |

| Groove Flanks B | ≤3.2μm | ≤16 μm |

| Note: It is recommended to have 50% to 90% of the working surface material contact area value. | ||

|

INSTALLATION NOTES |

||