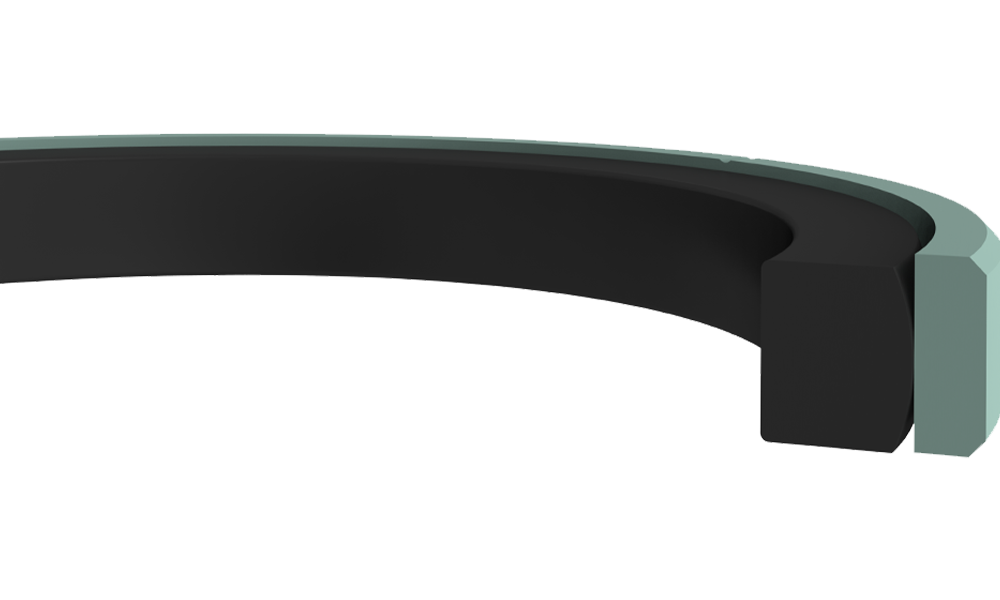

Piston Seal

| KASTAŞ NO | D(H8) | d(h8) | B(+0.2/-0.0) | r | n |

|---|---|---|---|---|---|

| K755-200-175 | 200 | 175 | 12,5 | 0,4 | 10 |

| K755-220-195 | 220 | 195 | 12.5 | 0.4 | 10 |

| K755-225-200 | 225 | 200 | 12.5 | 0.4 | 10 |

| K755-240-215 | 240 | 215 | 12.5 | 0.4 | 12 |

| K755-250-220 | 250 | 220 | 15 | 0.8 | 12 |

| K755-260-230 | 260 | 230 | 15 | 0.8 | 12 |

| K755-320-290 | 320 | 290 | 15 | 0.8 | 12 |

| K755-325-295 | 325 | 295 | 15 | 0,8 | 12 |

| K755-327.5-297.5 | 327.5 | 297.5 | 15 | 0.8 | 12 |

| K755-340-310 | 340 | 310 | 15 | 0.8 | 12 |

| K755-350-320 | 350 | 320 | 14 | 0.8 | 12 |

| K755-355-325 | 355 | 325 | 15 | 0,8 | 12 |

| K755-360-330 | 360 | 330 | 15 | 0.8 | 12 |

| K755-430-400 | 430 | 400 | 15 | 0.8 | 12 |

| K755-460-430 | 460 | 430 | 14 | 1.2 | 12 |

| K755-490-460 | 490 | 460 | 15 | 1.2 | 12 |

| K755-540-505 | 540 | 505 | 17.5 | 1.20 | 12 |

| K755-590-555 | 590 | 555 | 17.5 | 1.2 | 12 |

|

||||||||||||||

|

K755 is a two piecedouble acting piston seal which consists of one energizing elastomer ring and special mixture thermoplastic ring. •Excellent performance in large diameter cylinders and heavy duty applications •Long service life •High sliding speed •Wide range of temperature and chemicals depending on the o-ring material •Minimum static and dynamic friction coefficient for a minimum energy loss •Simple groove design and low axial housing heights •No twisting in the housing APPLICATION Steel industry , injection moulding machines , presses , large diameter cylinders , steel industry |

||||||||||||||

|

||||||||||||||

|

||||||||||||||

| SURFACE ROUGHNESS | Ra | Rmax | ||||||||||||||||||||||||||||||||

| Sliding Surface ØD | ≤0.2 μm | ≤2.0μm | ||||||||||||||||||||||||||||||||

| Groove Base Ød | ≤1.6 μm | ≤6.3μm | ||||||||||||||||||||||||||||||||

| Groove Flanks B | ≤3.2 μm | ≤16 μm | ||||||||||||||||||||||||||||||||

| Note: It is recommended to have 50% to 90% of the working surface material contact area value. | ||||||||||||||||||||||||||||||||||

|

INSTALLATION NOTES |

||||||||||||||||||||||||||||||||||

Note: All the above mentioned "S" values are maximum and it's vital to use lower values for system security. |

||||||||||||||||||||||||||||||||||