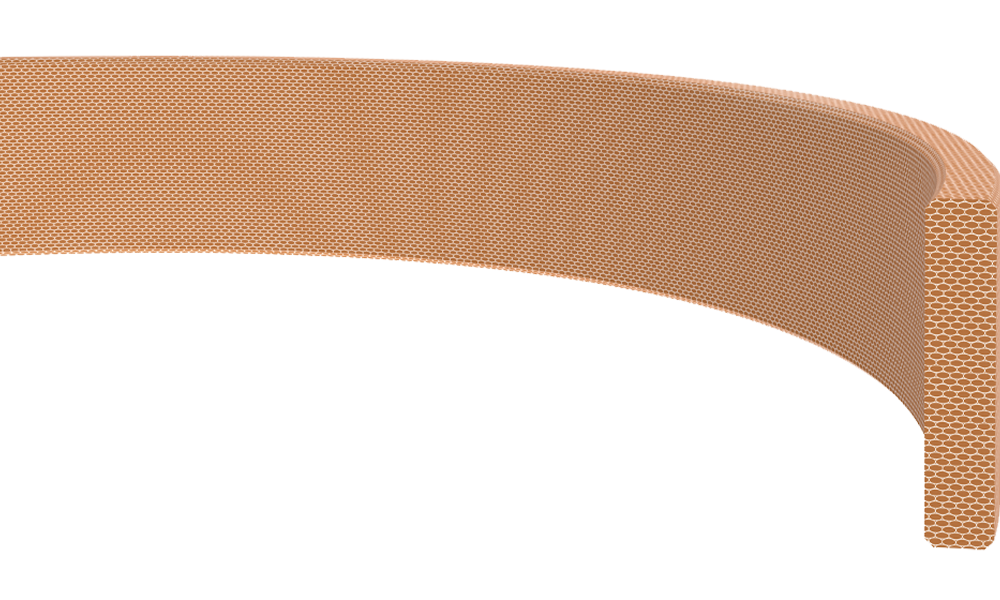

K75

Piston Rod Guide Ring

| KASTAS NO | d(f8) dp (h8) | Db(H8) D(H9) | B(-0/+0,2) | b | d1 (h9) | D1 (H9) | k |

|---|---|---|---|---|---|---|---|

| K75-025 | 25 | 30 | 9,7 | 9,5 | 28,2 | 26,8 | 1 |

| K75-030 | 30 | 35 | 9.7 | 9.5 | 33.2 | 31.8 | 1 |

| K75-035 | 35 | 40 | 15 | 14.8 | 38.2 | 36.8 | 1 |

| K75-040/1 | 40 | 45 | 9.7 | 9.5 | 43.2 | 41.8 | 1.5 |

| K75-040/2 | 40 | 45 | 15 | 14.8 | 43.2 | 41.8 | 1.5 |

| K75-045 | 45 | 50 | 9.7 | 9.5 | 48.2 | 46.8 | 1.5 |

| K75-045/1 | 45 | 50 | 15 | 14.8 | 48.2 | 46.8 | 1.5 |

| K75-050 | 50 | 55 | 9.7 | 9.5 | 53.2 | 51.8 | 2 |

| K75-050/1 | 50 | 55 | 15 | 14.8 | 53.2 | 51.8 | 2 |

| K75-050/2 | 50 | 54 | 10 | 9.8 | 53 | 51 | 2 |

| K75-055 | 55 | 60 | 15 | 14.8 | 58.2 | 56.8 | 2 |

| K75-055/1 | 55 | 60 | 9.7 | 9.5 | 58.2 | 56.8 | 2 |

| K75-058 | 58 | 63 | 9.7 | 9.5 | 61.2 | 59.8 | 2 |

| K75-060 | 60 | 65 | 15 | 14.8 | 63.2 | 61.8 | 2.5 |

| K75-060/1 | 60 | 65 | 9.7 | 9.5 | 63.2 | 61.8 | 2.5 |

| K75-060/2 | 60 | 65 | 20 | 19.8 | 63.2 | 61.8 | 2.5 |

| K75-063 | 63 | 68 | 15 | 14.8 | 66.2 | 64.8 | 2.5 |

| K75-065 | 65 | 70 | 15 | 14.8 | 68.2 | 66.8 | 2.5 |

| K75-065/1 | 65 | 70 | 9.7 | 9.5 | 68.2 | 66.8 | 2.5 |

| K75-070 | 70 | 75 | 9.7 | 9.5 | 73.2 | 71.8 | 2.5 |

| K75-070/1 | 70 | 75 | 15 | 14.8 | 73.2 | 71.8 | 2.5 |

| K75-074 | 74 | 80 | 6.5 | 6.3 | 77.6 | 76.4 | 2.5 |

| K75-075 | 75 | 80 | 9.7 | 9.5 | 78.2 | 76.8 | 2.5 |

| K75-075/1 | 75 | 80 | 15 | 14.8 | 78.2 | 76.8 | 2.5 |

| K75-080 | 80 | 85 | 9.7 | 9.5 | 83.2 | 81.8 | 2.5 |

| K75-080/1 | 80 | 85 | 15 | 14.8 | 83.2 | 81.8 | 2.5 |

| K75-080/2 | 80 | 85 | 20 | 19.8 | 83.2 | 81.8 | 2.5 |

| K75-084 | 84 | 90 | 6.5 | 6.3 | 87.6 | 86.4 | 2.5 |

| K75-085 | 85 | 90 | 9.7 | 9.5 | 88.2 | 86.8 | 2.5 |

| K75-085/1 | 85 | 90 | 15 | 14.8 | 88.2 | 86.8 | 2.5 |

| K75-090 | 90 | 95 | 15 | 14.8 | 93.2 | 91.8 | 2.5 |

| K75-090/1 | 90 | 95 | 9.7 | 9.5 | 93.2 | 91.8 | 2.5 |

| K75-090/2 | 90 | 95 | 5.7 | 5.4 | 93.2 | 91.8 | 2.5 |

| K75-094 | 94 | 100 | 6.5 | 6.3 | 97.2 | 95.8 | 2.5 |

| K75-095 | 95 | 100 | 9.7 | 9.5 | 98.2 | 96.8 | 2.5 |

| K75-095/1 | 95 | 100 | 15 | 14.8 | 98.2 | 96.8 | 2.5 |

| K75-100 | 100 | 105 | 15 | 14.8 | 103.2 | 101.8 | 3.5 |

| K75-100/1 | 100 | 105 | 9.7 | 9.5 | 103.2 | 101.8 | 3.5 |

| K75-100/2 | 100 | 105 | 20 | 19.8 | 103.2 | 101.8 | 3.5 |

| K75-100/3 | 100 | 105 | 25 | 24,8 | 103,2 | 101,8 | 3,5 |

| K75-105 | 105 | 110 | 9.7 | 9.5 | 108.2 | 106.8 | 3.5 |

| K75-105/1 | 105 | 110 | 15 | 14.8 | 108.2 | 106.8 | 3.5 |

| K75-105/3 | 105 | 110 | 20 | 19.8 | 108.2 | 106.8 | 3.5 |

| K75-110 | 110 | 115 | 9.7 | 9.5 | 113.2 | 111.8 | 3.5 |

| K75-110/1 | 110 | 115 | 15 | 14.8 | 113.2 | 111.8 | 3.5 |

| K75-115 | 115 | 120 | 9.7 | 9.5 | 118.2 | 116.8 | 3.5 |

| K75-115/1 | 115 | 120 | 15 | 14.8 | 118.2 | 116.8 | 3.5 |

| K75-115/2 | 115 | 120 | 25 | 24,8 | 118,2 | 116,8 | 3,5 |

| K75-120 | 120 | 125 | 9.7 | 9.5 | 123.2 | 121.8 | 3.5 |

| K75-120/1 | 120 | 125 | 15 | 14.8 | 123.2 | 121.8 | 3.5 |

| K75-120/2 | 120 | 125 | 20 | 19.8 | 123.2 | 121.8 | 3.5 |

| K75-125 | 125 | 130 | 9.7 | 9.5 | 128.2 | 126.8 | 3.5 |

| K75-125/1 | 125 | 130 | 15 | 14.8 | 128.2 | 126.8 | 3.5 |

| K75-130 | 130 | 135 | 9.7 | 9.5 | 133.2 | 131.8 | 3.5 |

| K75-130/1 | 130 | 135 | 15 | 14.8 | 133.2 | 131.8 | 3.5 |

| K75-135 | 135 | 140 | 9.7 | 9.5 | 138.2 | 136.8 | 3.5 |

| K75-135/1 | 135 | 140 | 15 | 14.8 | 138.2 | 136.8 | 3.5 |

| K75-140 | 140 | 145 | 9.7 | 9.5 | 143.2 | 141.8 | 3.5 |

| K75-140/1 | 140 | 145 | 15 | 14.8 | 143.2 | 141.8 | 3.5 |

| K75-140/2 | 140 | 148 | 25 | 24,8 | 143,2 | 141,8 | 3,5 |

| K75-142 | 142 | 147 | 15 | 14.8 | 145.2 | 143.8 | 3.5 |

| K75-145 | 145 | 150 | 9.7 | 9.5 | 148.2 | 146.8 | 3.5 |

| K75-145/1 | 145 | 150 | 15 | 14.8 | 148.2 | 146.8 | 3.5 |

| K75-145/2 | 145 | 150 | 25 | 24,8 | 148,2 | 146,8 | 3,5 |

| K75-150 | 150 | 155 | 15 | 14.8 | 153.2 | 151.8 | 3.5 |

| K75-150/1 | 150 | 155 | 9.7 | 9.5 | 153.2 | 151.8 | 3.5 |

| K75-155 | 155 | 160 | 9.7 | 9.5 | 158.2 | 156.8 | 3.5 |

| K75-155/1 | 155 | 160 | 15 | 14.8 | 158.2 | 156.8 | 3.5 |

| K75-155/2 | 155 | 163 | 25 | 24.8 | 158.2 | 156.8 | 3.5 |

| K75-155/3 | 155 | 160 | 20 | 19,8 | 158,2 | 156,8 | 3,5 |

| K75-160 | 160 | 165 | 20 | 19,8 | 163,2 | 161,8 | 3,5 |

| K75-165 | 165 | 170 | 9.7 | 9.5 | 168.2 | 166.8 | 3.5 |

| K75-175 | 175 | 180 | 9.7 | 9.5 | 178.2 | 176.8 | 3.5 |

| K75-175/1 | 175 | 180 | 15 | 14.8 | 178.2 | 176.8 | 3.5 |

| K75-180 | 180 | 185 | 15 | 14.8 | 183.2 | 181.8 | 3.5 |

| K75-180/1 | 180 | 188 | 25 | 24,8 | 186,2 | 181,8 | 3,5 |

| K75-185 | 185 | 190 | 9.7 | 9.5 | 188.2 | 186.8 | 3.5 |

| K75-185/1 | 185 | 190 | 15 | 14.8 | 188.2 | 186.8 | 3.5 |

| K75-192 | 192 | 200 | 25 | 24,8 | 198,2 | 193,8 | 3,5 |

| K75-195 | 195 | 200 | 9.7 | 9.5 | 198.2 | 196.8 | 3.5 |

| K75-195/1 | 195 | 200 | 15 | 14.8 | 198.2 | 196.8 | 3.5 |

| K75-200 | 200 | 205 | 15 | 14.8 | 203.2 | 201.8 | 4.5 |

| K75-200/1 | 200 | 208 | 25 | 24,8 | 206,2 | 201,8 | 4,5 |

| K75-210 | 210 | 218 | 25 | 24,8 | 216,2 | 211,8 | 4,5 |

| K75-212 | 212 | 220 | 25 | 24.8 | 218.2 | 213.8 | 4.5 |

| K75-215 | 215 | 220 | 15 | 14.8 | 218.2 | 216.8 | 4.5 |

| K75-225 | 225 | 230 | 15 | 14.8 | 228.2 | 226.8 | 4.5 |

| K75-240 | 240 | 245 | 15 | 14.8 | 243.2 | 241.8 | 4.5 |

| K75-240/1 | 240 | 248 | 25 | 24,8 | 246,2 | 241,8 | 4,5 |

| K75-242 | 242 | 250 | 25 | 24,8 | 245,2 | 243,8 | 4,5 |

| K75-245 | 245 | 250 | 9.7 | 9.5 | 248.2 | 246.8 | 4.5 |

| K75-245/1 | 245 | 250 | 15 | 14.8 | 248.2 | 246.8 | 4.5 |

| K75-265 | 265 | 270 | 15 | 14.8 | 268.2 | 266.8 | 4.5 |

| K75-275 | 275 | 280 | 9.7 | 9.5 | 278.2 | 276.8 | 4.5 |

| K75-290 | 290 | 298 | 25 | 24,8 | 296,2 | 291,8 | 4,5 |

| K75-292 | 292 | 300 | 25 | 24,8 | 298,2 | 293,8 | 4,5 |

| K75-295 | 295 | 300 | 15 | 14.8 | 298.2 | 296.8 | 4.5 |

| K75-342 | 342 | 350 | 25 | 24,8 | 348,2 | 343,8 | 4,5 |

| K75-392 | 392 | 400 | 25 | 24,8 | 398,2 | 393,8 | 4,5 |

|

||||||||||||||||||||||||||||

|

K 75 is a piston - rod guide ring designed to be used in heavy dutyhydraulic and pneumatic systems. PRODUCT ADVANTAGES APPLICATION |

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

| SURFACE ROUGHNESS | Ra | Rmax |

| Sliding Surface ØD-Ød | ≤0.4µm | ≤3.2 μm |

| Groove Base ØDb-Ødp | ≤1.6µm |

≤10 µm |

| Groove Flanks B | ≤3.2µm | ≤14 µm |

|

INSTALLATION NOTES |

||