Spring Loaded Piston Seal

| KASTAŞ NO | D (H9) | d (h9) | B (-0/+0,2) | amin. | n |

|---|---|---|---|---|---|

| K751-006 | 6 | 3.1 | 2.4 | 0.4 | 1.8 |

| K751-010 | 10 | 7,1 | 2,4 | 0,4 | 1,8 |

| K751-020 | 20 | 15,5 | 3,6 | 0,6 | 2,8 |

| K751-025 | 25 | 18.8 | 4.8 | 0.7 | 3.8 |

| K751-030 | 30 | 23,8 | 4,8 | 0,7 | 3,8 |

| K751-040 | 40 | 33,8 | 4,8 | 0,7 | 3,8 |

| K751-050 | 50 | 40,6 | 7,1 | 0,8 | 5,6 |

| K751-060 | 60 | 50,6 | 7,1 | 0,8 | 5,6 |

| K751-063 | 63 | 53,6 | 7,1 | 0,8 | 5,6 |

| K751-070 | 70 | 60,6 | 7,1 | 0,8 | 5,6 |

| K751-075 | 75 | 65.6 | 7.1 | 0.8 | 5.6 |

| K751-080 | 80 | 70,6 | 7,1 | 0,8 | 5,6 |

| K751-085 | 85 | 75,6 | 7,1 | 0,8 | 5,6 |

| K751-090 | 90 | 80,6 | 7,1 | 0,8 | 5,6 |

| K751-100 | 100 | 90,6 | 7,1 | 0,8 | 5,6 |

| K751-110 | 110 | 100,6 | 7,1 | 0,8 | 5,6 |

| K751-115 | 124.4 | 115 | 7.1 | 0.8 | 5.6 |

| K751-120 | 120 | 110,6 | 7,1 | 0,8 | 5,6 |

| K751-125 | 125 | 112.8 | 9.5 | 0.8 | 7.6 |

| K751-130 | 130 | 117,8 | 9,5 | 0,8 | 7,6 |

| K751-140 | 140 | 127,8 | 9,5 | 0,8 | 7,6 |

| K751-150 | 150 | 137,8 | 9,5 | 0,8 | 7,6 |

| K751-160 | 160 | 147,8 | 9,5 | 0,8 | 7,6 |

| K751-170 | 170 | 157,8 | 9,5 | 0,8 | 7,6 |

| K751-200 | 200 | 187.8 | 9.5 | 0.8 | 7.6 |

|

|||||||||||||

|

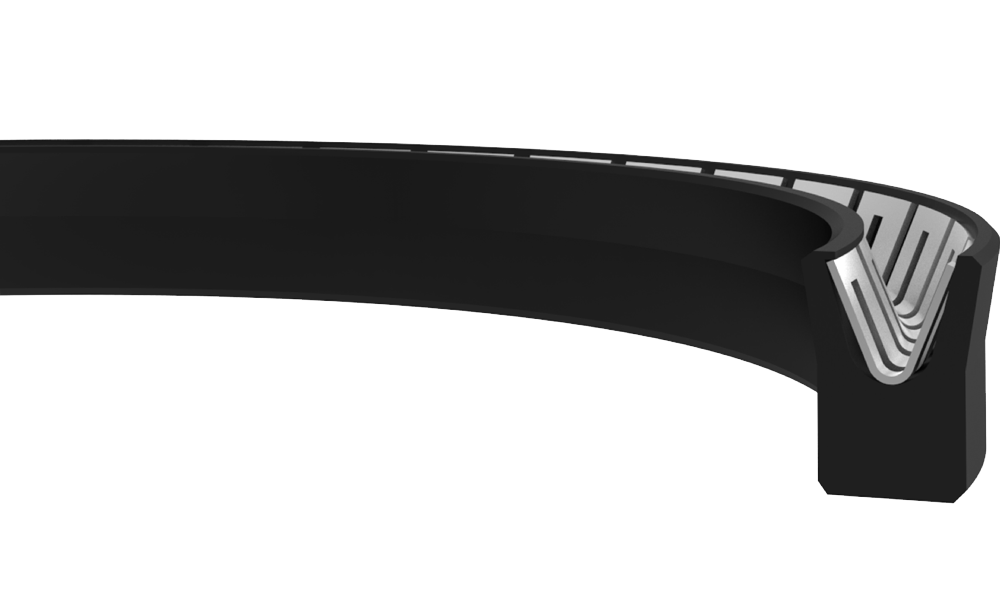

K751 is a two piece single acting piston seal which consists of a PTFE u-ring with metal spring as a tension component. PRODUCT ADVANTAGES APPLICATION |

|||||||||||||

|

|||||||||||||

|

|||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||